It seems we can’t find what you’re looking for. Perhaps searching can help.

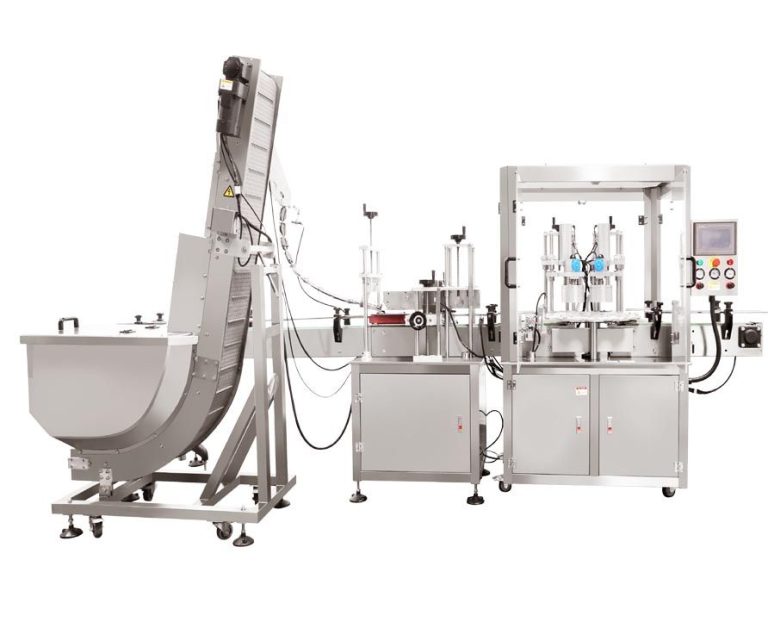

“The Revolutionary Automatic Double Head Glass Bottle Vacuum Capper: A Closer Look”

In the ever-evolving landscape of packaging technology, the Automatic Double Head Glass Bottle Vacuum Capper stands out as a revolutionary innovation. Let’s take a closer look at what makes this machine so remarkable. This advanced capper is engineered with precision and functionality in mind. The dual-head design is a game-changer,…