Table of Contents

Benefits of Using a Labeling Machine for Packaging

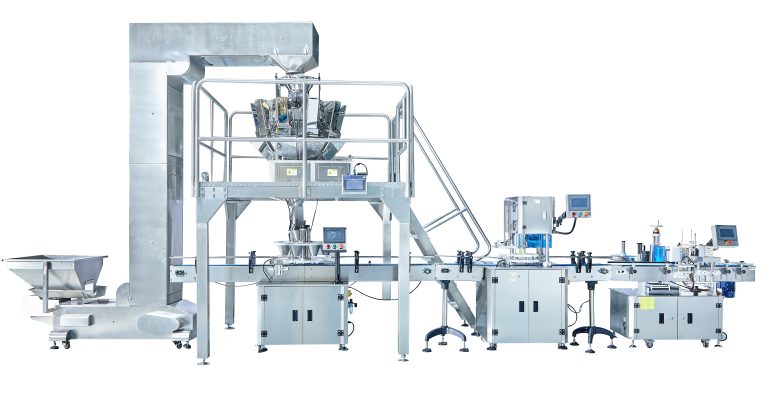

In today’s fast-paced world, efficiency and accuracy are key factors in the success of any business. When it comes to packaging products, having a reliable labeling machine can make a significant difference in streamlining the process and ensuring that your products are properly labeled. Labeling machines have revolutionized the way companies package their products, offering a wide range of benefits that can help improve productivity and reduce costs.

One of the primary benefits of using a labeling machine is the speed at which it can apply labels to products. Manual labeling can be a time-consuming and labor-intensive process, especially when dealing with large volumes of products. A labeling machine can apply labels quickly and accurately, significantly reducing the time it takes to package products. This increased speed can help companies meet tight deadlines and improve overall efficiency in their packaging operations.

In addition to speed, labeling machines also offer a high level of accuracy when applying labels to products. Manual labeling can be prone to errors, such as crooked or misplaced labels, which can affect the overall appearance and quality of the product. Labeling machines are designed to apply labels with precision, ensuring that each label is placed correctly and consistently on every product. This level of accuracy can help improve the overall presentation of products and enhance the brand image of a company.

Another benefit of using a labeling machine is the versatility it offers in terms of label design and application. Labeling machines can accommodate a wide range of label sizes and shapes, allowing companies to customize their labels to meet their specific branding and packaging requirements. Whether you need to apply simple text labels or complex barcode labels, a labeling machine can handle a variety of label designs with ease. This versatility can help companies create unique and eye-catching packaging that sets their products apart from the competition.

In addition to speed, accuracy, and versatility, labeling machines also offer cost savings for companies. While the initial investment in a labeling machine may seem significant, the long-term savings can outweigh the upfront costs. By automating the labeling process, companies can reduce labor costs associated with manual labeling and minimize the risk of errors that can lead to costly rework. Additionally, labeling machines can help companies optimize their packaging operations, leading to increased productivity and efficiency that can result in overall cost savings.

Overall, using a labeling machine for packaging offers a wide range of benefits that can help companies improve their packaging operations and enhance the quality of their products. From increased speed and accuracy to versatility and cost savings, labeling machines are a valuable tool for companies looking to streamline their packaging processes and stay ahead of the competition. By investing in a labeling machine, companies can revolutionize their packaging operations and take their products to the next level.

How to Choose the Right Labeling Machine for Your Packaging Needs

Packaging plays a crucial role in the success of any product. It not only protects the product but also serves as a marketing tool to attract customers. One of the key elements of packaging is labeling. Labels provide important information about the product, such as its ingredients, expiration date, and usage instructions. In today’s fast-paced world, manual labeling can be time-consuming and prone to errors. This is where labeling machines come in.

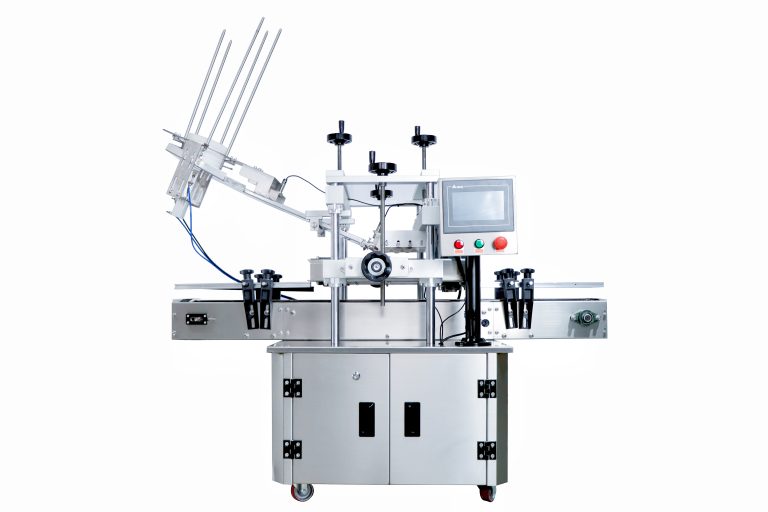

Labeling machines are automated devices that apply labels to products quickly and accurately. They can significantly increase efficiency and productivity in packaging operations. However, with so many options available in the market, choosing the right labeling machine for your packaging needs can be a daunting task. In this comprehensive guide, we will discuss the factors to consider when selecting a labeling machine.

The first step in choosing a labeling machine is to determine your packaging requirements. Consider the size and shape of your products, as well as the type of labels you will be using. Some labeling machines are designed for specific types of labels, such as wrap-around labels or top labels. Make sure the machine you choose is compatible with the labels you plan to use.

Next, consider the speed and capacity of the labeling machine. How many products do you need to label per minute? Some labeling machines can label hundreds of products per minute, while others are more suitable for smaller production runs. Choose a machine that can keep up with your production demands without compromising on quality.

Another important factor to consider is the accuracy of the labeling machine. Look for a machine that can apply labels consistently and precisely, without wrinkles or bubbles. This is especially important for products with small or irregularly shaped packaging. Some labeling machines come with sensors and adjustable settings to ensure accurate label placement.

Ease of use and maintenance are also important considerations when choosing a labeling machine. Look for a machine that is user-friendly and easy to set up. Consider the training and support provided by the manufacturer. A labeling machine that is easy to maintain will save you time and money in the long run.

Finally, consider the cost of the labeling machine. While it may be tempting to choose the cheapest option, keep in mind that quality and reliability are important factors to consider. Look for a labeling machine that offers a good balance of price and performance. Consider the long-term costs of maintenance and repairs when making your decision.

In conclusion, choosing the right labeling machine for your packaging needs is a crucial decision that can have a significant impact on your business. Consider factors such as packaging requirements, speed and capacity, accuracy, ease of use and maintenance, and cost when selecting a labeling machine. By taking the time to research and evaluate your options, you can revolutionize your packaging operations and take your business to the next level.

Tips for Maximizing Efficiency and Effectiveness with a Labeling Machine

In today’s fast-paced business world, efficiency and effectiveness are key factors in staying competitive. One way to streamline your packaging process and improve overall productivity is by investing in a labeling machine. These machines can revolutionize the way you label your products, saving you time and money in the long run. In this comprehensive guide, we will provide you with tips on how to maximize efficiency and effectiveness with a labeling machine.

First and foremost, it is essential to choose the right labeling machine for your specific needs. There are various types of labeling machines available on the market, each designed for different purposes. Whether you need a machine for applying labels to bottles, boxes, or other types of packaging, it is crucial to select a machine that is tailored to your requirements. Consider factors such as the size and shape of your products, the type of labels you will be using, and the speed at which you need to label your products.

Once you have selected the right labeling machine for your needs, it is important to ensure that it is properly set up and calibrated. This includes adjusting the machine’s settings to match the size and shape of your products, as well as calibrating the machine to apply labels accurately and consistently. Proper calibration is essential for ensuring that your labels are applied correctly every time, reducing the risk of errors and wastage.

In addition to proper setup and calibration, it is also important to regularly maintain and clean your labeling machine. Regular maintenance will help prevent breakdowns and ensure that your machine operates smoothly and efficiently. Cleaning your machine regularly will also help prevent the buildup of dirt and debris, which can affect the quality of your labels. Be sure to follow the manufacturer’s guidelines for maintenance and cleaning to keep your labeling machine in top condition.

Another tip for maximizing efficiency and effectiveness with a labeling machine is to invest in high-quality labels and label materials. Using high-quality labels will ensure that your products are labeled accurately and professionally, enhancing the overall appearance of your packaging. Additionally, using durable label materials will help prevent labels from peeling or fading over time, ensuring that your products remain well-labeled throughout their shelf life.

Furthermore, it is important to train your staff on how to use the labeling machine properly. Proper training will help ensure that your employees are able to operate the machine safely and efficiently, reducing the risk of accidents and errors. Provide your staff with thorough training on how to load labels into the machine, adjust settings, and troubleshoot common issues. Regular training sessions will help keep your staff up to date on the latest techniques and best practices for using the labeling machine.

In conclusion, a labeling machine can be a valuable asset for streamlining your packaging process and improving overall efficiency and effectiveness. By choosing the right machine, properly setting it up and calibrating it, maintaining and cleaning it regularly, using high-quality labels and label materials, and training your staff on how to use it properly, you can maximize the benefits of a labeling machine in your business. Follow these tips to revolutionize your packaging process and take your labeling to the next level.