Table of Contents

Benefits of Using a Linear Type Dustproof Lid Capping Machine

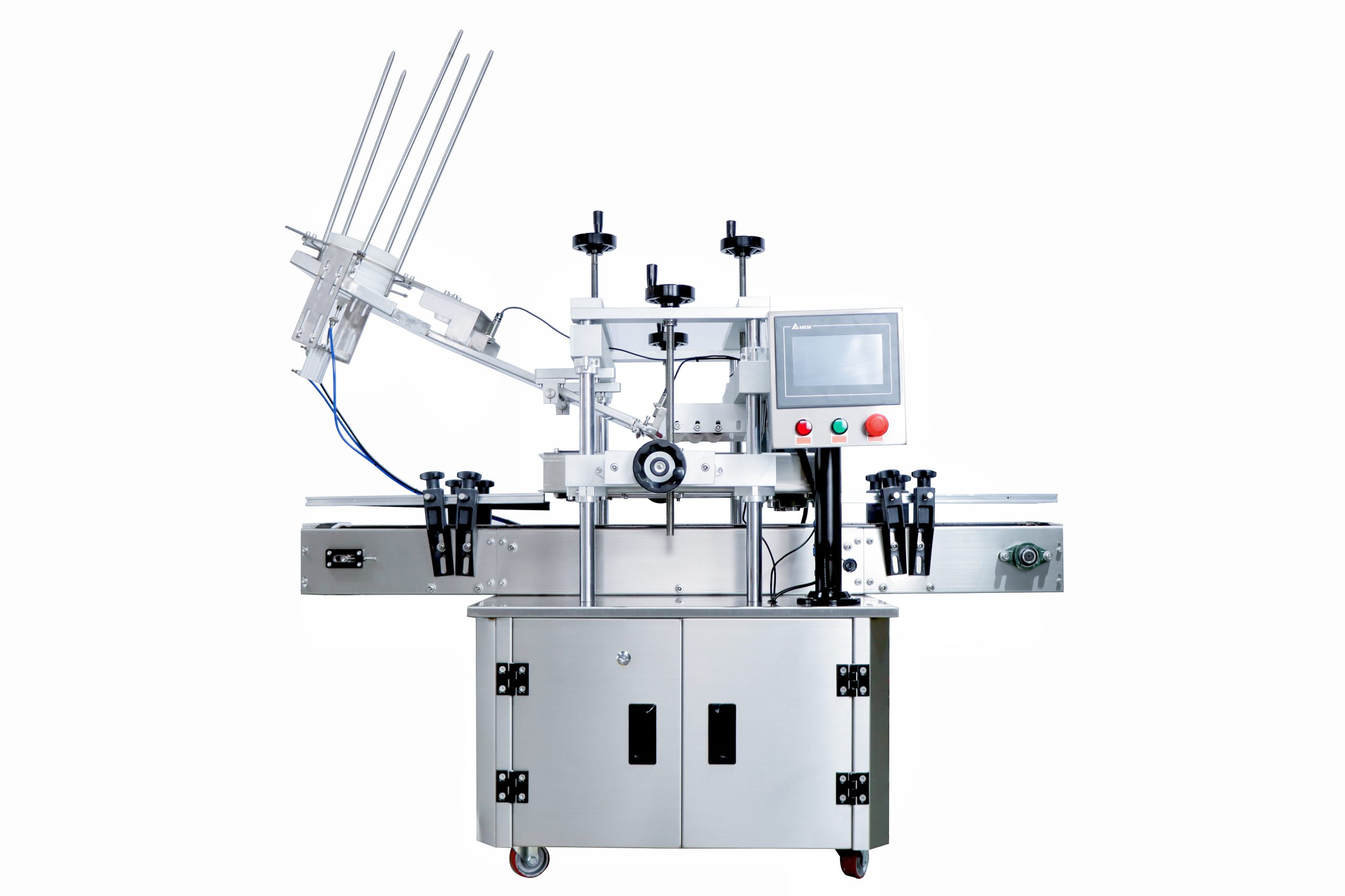

In the world of manufacturing and packaging, efficiency and precision are key factors in ensuring the success of a product. One important aspect of this process is the sealing of containers with lids, which helps to protect the contents from contamination and maintain their freshness. A Linear Type Dustproof Lid Capping Machine is a valuable tool that can streamline this process and provide numerous benefits to businesses.

One of the primary advantages of using a Linear Type Dustproof Lid Capping Machine is its ability to cap containers quickly and accurately. This machine is designed to handle a high volume of containers in a linear fashion, allowing for a continuous and efficient capping process. With its automated operation, the machine can cap lids with precision and consistency, reducing the risk of human error and ensuring a tight seal on each container.

In addition to its speed and accuracy, a Linear Type Dustproof Lid Capping Machine is also designed to be dustproof, which is crucial for maintaining the quality and integrity of the product being packaged. Dust and other contaminants can compromise the contents of a container, leading to spoilage or contamination. By using a dustproof capping machine, businesses can ensure that their products remain safe and protected throughout the packaging process.

Furthermore, a Linear Type Dustproof Lid Capping Machine is versatile and can be easily adjusted to accommodate different container sizes and lid types. This flexibility allows businesses to streamline their packaging process and adapt to changing production needs without having to invest in multiple machines. With its adjustable settings, the machine can cap lids of various sizes and shapes, making it a cost-effective solution for businesses of all sizes.

Another benefit of using a Linear Type Dustproof Lid Capping Machine is its durability and reliability. These machines are built to withstand the rigors of continuous use in a manufacturing environment, ensuring long-term performance and minimal downtime. With proper maintenance and care, a capping machine can provide years of reliable service, helping businesses to meet their production goals and maintain high-quality standards.

In conclusion, a Linear Type Dustproof Lid Capping Machine offers numerous benefits to businesses looking to streamline their packaging process and ensure the quality of their products. From its speed and accuracy to its dustproof design and versatility, this machine is a valuable asset for any manufacturing operation. By investing in a capping machine, businesses can improve efficiency, reduce waste, and protect their products from contamination, ultimately leading to increased customer satisfaction and profitability.

How to Choose the Right Linear Type Dustproof Lid Capping Machine for Your Business

When it comes to choosing the right equipment for your business, there are many factors to consider. One important piece of machinery that can make a big difference in your production process is a linear type dustproof lid capping machine. This type of machine is designed to efficiently cap lids on containers while also keeping dust and other contaminants out of the product. In this article, we will discuss some key considerations to keep in mind when selecting a linear type dustproof lid capping machine for your business.

First and foremost, it is important to consider the size and shape of the containers that you will be capping. Linear type dustproof lid capping machines come in a variety of sizes and configurations to accommodate different container sizes and shapes. Make sure to choose a machine that is compatible with the containers you will be using in your production process to ensure a smooth and efficient capping process.

Another important factor to consider is the speed and efficiency of the machine. Depending on the volume of production in your business, you may need a machine that can cap lids quickly and accurately. Look for a machine that offers high-speed capping capabilities without sacrificing precision. This will help you meet production deadlines and maintain consistent quality in your products.

In addition to speed and efficiency, it is also important to consider the durability and reliability of the machine. A linear type dustproof lid capping machine is a significant investment for your business, so you want to make sure that it will last for years to come. Look for a machine that is made from high-quality materials and has a reputation for reliability. This will help minimize downtime and maintenance costs in the long run.

Furthermore, consider the ease of use and maintenance of the machine. A user-friendly machine will help your operators quickly learn how to operate it effectively, leading to increased productivity and efficiency. Additionally, a machine that is easy to maintain will help reduce downtime and repair costs. Look for a machine that comes with clear instructions and easy-to-access parts for maintenance and repairs.

Lastly, consider the overall cost of the machine, including upfront costs, operating costs, and potential return on investment. While it may be tempting to choose the cheapest option available, it is important to weigh the cost against the features and benefits of the machine. A higher upfront cost may be justified if the machine offers increased speed, efficiency, and durability, leading to long-term cost savings and improved productivity.

In conclusion, choosing the right linear type dustproof lid capping machine for your business is a crucial decision that can impact your production process and overall efficiency. Consider factors such as container size and shape, speed and efficiency, durability and reliability, ease of use and maintenance, and overall cost when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure a smooth and efficient capping process that helps drive the success of your business.

Maintenance Tips for Keeping Your Linear Type Dustproof Lid Capping Machine in Top Condition

Maintaining your linear type dustproof lid capping machine is essential to ensure its optimal performance and longevity. Regular maintenance not only helps prevent breakdowns and costly repairs but also ensures that your machine operates efficiently, producing high-quality capped products consistently. In this article, we will discuss some maintenance tips to help you keep your linear type dustproof lid capping machine in top condition.

First and foremost, it is crucial to follow the manufacturer’s guidelines for maintenance and servicing. These guidelines are designed to help you properly care for your machine and prevent any potential issues. Regularly inspecting your machine for any signs of wear and tear, such as loose or damaged parts, can help you identify and address problems before they escalate.

Cleaning your linear type dustproof lid capping machine regularly is also essential. Dust, debris, and other contaminants can accumulate on the machine’s components, affecting its performance and potentially causing damage. Use a soft brush or cloth to remove any buildup and ensure that the machine is clean and free of any obstructions.

In addition to cleaning, lubricating the moving parts of your machine is crucial for its smooth operation. Lubrication helps reduce friction and wear on the components, extending the machine’s lifespan. Be sure to use the appropriate lubricant recommended by the manufacturer and apply it according to the specified intervals.

Inspecting the machine’s belts, chains, and other mechanical components is another important maintenance task. Check for any signs of wear, such as cracks, fraying, or stretching, and replace any damaged parts promptly. Proper tensioning of belts and chains is also essential to prevent slippage and ensure smooth operation.

Regularly calibrating your linear type dustproof lid capping machine is necessary to maintain its accuracy and consistency. Over time, the machine’s settings may drift, affecting the quality of the capped products. Follow the manufacturer’s instructions for calibration and make any necessary adjustments to ensure that the machine is operating correctly.

Lastly, keeping a detailed maintenance log can help you track the upkeep of your linear type dustproof lid capping machine and identify any recurring issues. Record the dates of maintenance tasks, such as cleaning, lubrication, and inspections, as well as any repairs or replacements made. This information can help you schedule future maintenance and identify any patterns or trends that may require attention.

In conclusion, proper maintenance is essential for keeping your linear type dustproof lid capping machine in top condition. By following the manufacturer’s guidelines, cleaning and lubricating the machine regularly, inspecting and replacing worn parts, calibrating the machine, and keeping a detailed maintenance log, you can ensure that your machine operates efficiently and produces high-quality capped products consistently. Investing time and effort in maintaining your machine will pay off in the long run, saving you time and money on repairs and replacements.