Semi-automatic nitrogen can sealers have emerged as a valuable tool in enhancing packaging efficiency. Let’s explore the various ways they achieve this improvement.

One of the primary ways these sealers boost efficiency is through their nitrogen-filling feature. By introducing nitrogen into the cans before sealing, they create an inert atmosphere that helps preserve the contents. This reduces spoilage and extends the shelf life of the products, minimizing the need for frequent re-packaging or product recalls.

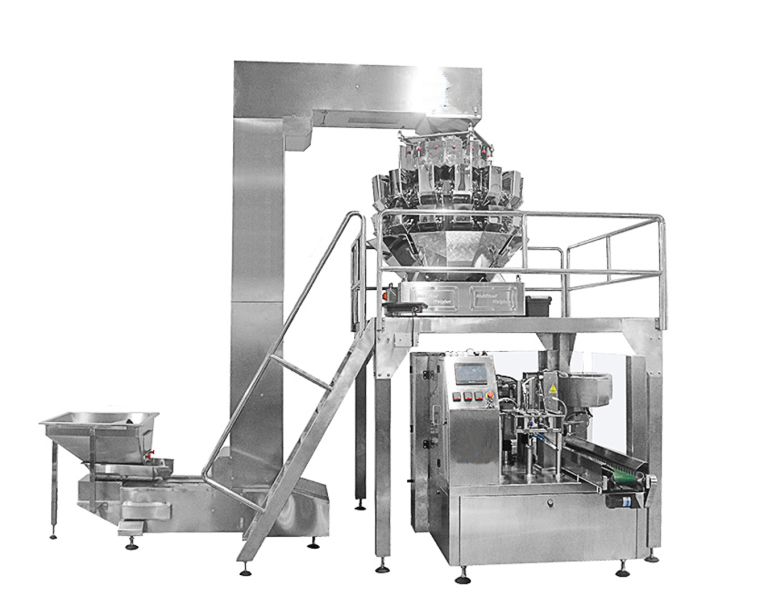

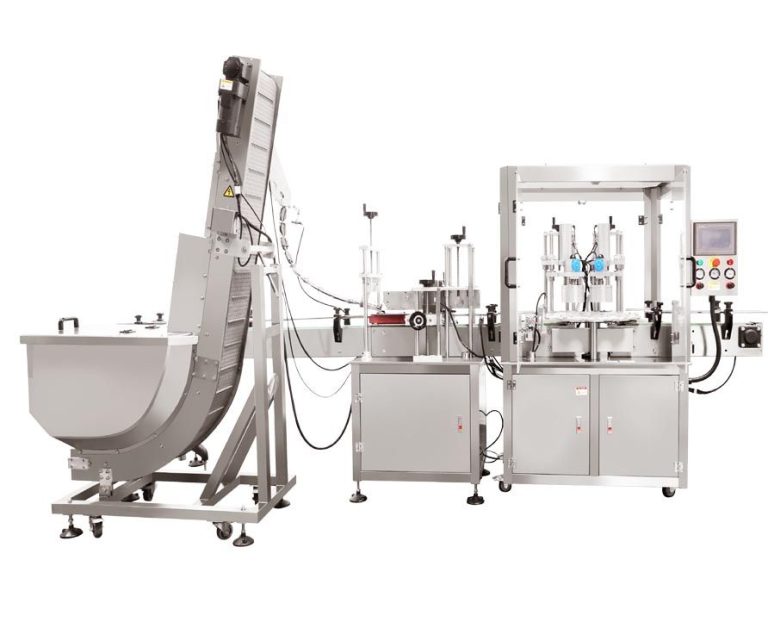

The semi-automatic operation strikes a balance between manual and fully automated processes. It allows for a quicker sealing process compared to manual methods while still providing some level of operator control and flexibility. This speeds up the packaging line without sacrificing the ability to handle unique or challenging packaging situations.

The precision and consistency of the sealing provided by these machines are crucial. Accurate and uniform seals ensure that each can is properly sealed the first time, reducing the number of defective packages. This not only saves time but also reduces material waste and rework.

Semi-automatic nitrogen can sealers are often designed to be easily integrated into existing packaging lines. Their compatibility and seamless connection with other equipment minimize disruptions and streamline the overall packaging workflow.

Moreover, these sealers can handle a significant volume of cans in a short period. Their durability and reliability ensure continuous operation with minimal breakdowns, maximizing productivity and minimizing downtime.

In conclusion, semi-automatic nitrogen can sealers improve packaging efficiency through nitrogen filling, optimized operation, precise sealing, seamless integration, and high productivity. They offer a practical and effective solution for businesses looking to enhance their packaging processes and increase output.