Table of Contents

Introduction

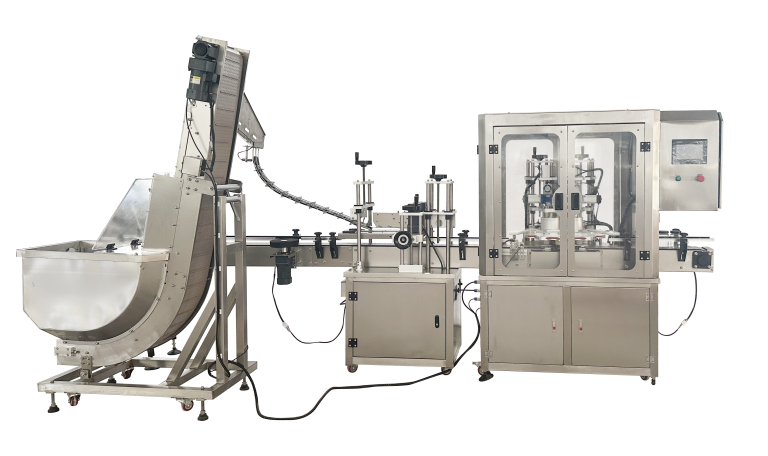

In the highly competitive business landscape, finding ways to enhance efficiency, quality, and profitability is crucial. One such innovation that can bring about a significant transformation in your business is the automatic single – side labeling machine. This advanced piece of equipment offers a multitude of benefits that can positively impact various aspects of your operations.

Improve Product Presentation

Precise Label Placement

A well – placed label is essential for creating a professional and appealing product image. The automatic single – side labeling machine uses advanced technology to ensure that labels are applied with extreme precision. Whether it’s a small cosmetic bottle or a large industrial container, the machine can accurately position the label, eliminating the risk of misaligned or crooked labels. This precision gives your products a consistent and high – quality look, which can significantly enhance their marketability.

Aesthetic Appeal

In addition to precision, the machine can handle a variety of label designs and materials. It can apply glossy, matte, or textured labels, adding a touch of elegance to your products. For example, in the food industry, a beautifully designed label with high – quality graphics can attract consumers’ attention on the supermarket shelves. The ability to create an aesthetically pleasing product presentation can set your brand apart from competitors and increase customer interest.

Enhance Operational Efficiency

High – Speed Labeling

Time is money in business, and the automatic single – side labeling machine offers remarkable speed. These machines can label a large number of products in a short period. For instance, in a busy manufacturing plant, it can label hundreds of items per minute, depending on the model and settings. This high – speed operation allows you to meet tight production deadlines and increase your overall output. You can fulfill large orders more quickly, which can lead to greater customer satisfaction and potentially more business opportunities.

Reduced Labor Requirements

Manual labeling is a labor – intensive process that requires a significant amount of time and manpower. By investing in an automatic single – side labeling machine, you can reduce your dependence on manual labor. One operator can oversee the machine’s operation, which can handle the labeling of many products simultaneously. This not only saves on labor costs but also frees up your employees to focus on other important tasks, such as quality control or customer service.

Ensure Labeling Accuracy

Compliance with Regulations

Many industries are subject to strict labeling regulations. In the pharmaceutical and food sectors, for example, labels must contain accurate information about ingredients, dosage, expiration dates, and safety warnings. The automatic single – side labeling machine can be programmed to print and apply labels with the correct information, ensuring that your products comply with all relevant regulations. This helps you avoid costly fines and legal issues that could arise from non – compliance.

Data Integrity

The machine can also be integrated with your business’s data management system. This allows for the accurate tracking of label information, such as batch numbers, production dates, and serial numbers. By maintaining data integrity, you can improve traceability in your supply chain. In case of a product recall or quality issue, you can quickly identify the affected products and take appropriate action, minimizing the impact on your business and customers.

Increase Cost – Effectiveness

Reduced Material Waste

Manual labeling often results in a certain amount of material waste due to misapplied labels or errors. The automatic single – side labeling machine, however, is highly efficient in its use of label materials. It cuts labels to the exact size required and applies them accurately on the first try, reducing waste. Over time, this can lead to significant savings on label material costs, especially for businesses that use a large volume of labels.

Long – Term Investment

While the initial cost of purchasing an automatic single – side labeling machine may seem substantial, it is a long – term investment. These machines are built to be durable and reliable, with a long service life. With proper maintenance, they can continue to operate efficiently for many years, providing a consistent return on your investment. Additionally, as your business grows, the machine can easily adapt to increased production demands, eliminating the need for frequent equipment upgrades.

Expand Product Range and Market Reach

Versatility in Labeling

The automatic single – side labeling machine is designed to be versatile. It can handle different types of products, including bottles, boxes, cans, and tubes. This means that if you decide to expand your product range, you can use the same machine to label the new products. For example, if you currently produce only bottled beverages and plan to introduce canned drinks, the machine can be adjusted to label the cans without the need for additional major investments.

Meeting Market Demands

By improving your labeling process, you can better meet the demands of the market. A well – labeled product is more likely to be accepted by consumers, both domestically and internationally. The ability to produce high – quality labeled products efficiently can help you enter new markets and increase your customer base. This can lead to increased sales and revenue for your business.

Conclusion

The automatic single – side labeling machine offers a wide range of benefits for your business. From improving product presentation and operational efficiency to ensuring labeling accuracy and increasing cost – effectiveness, it is a valuable asset that can drive your business forward. By investing in this technology, you can gain a competitive edge in the market and position your business for long – term success.