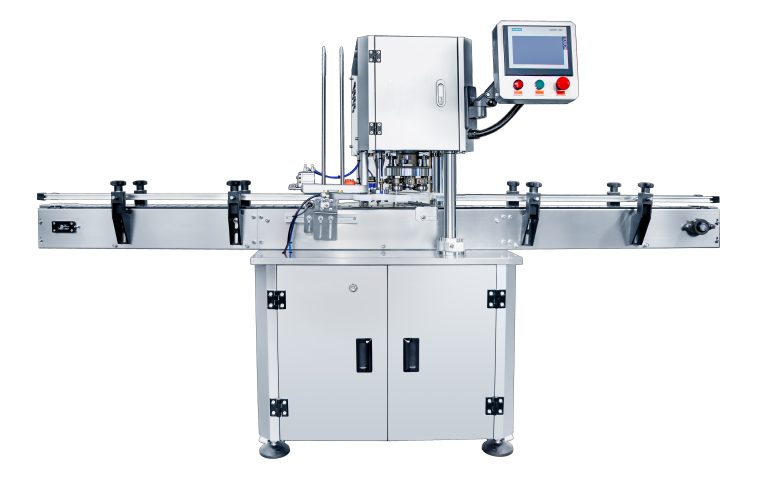

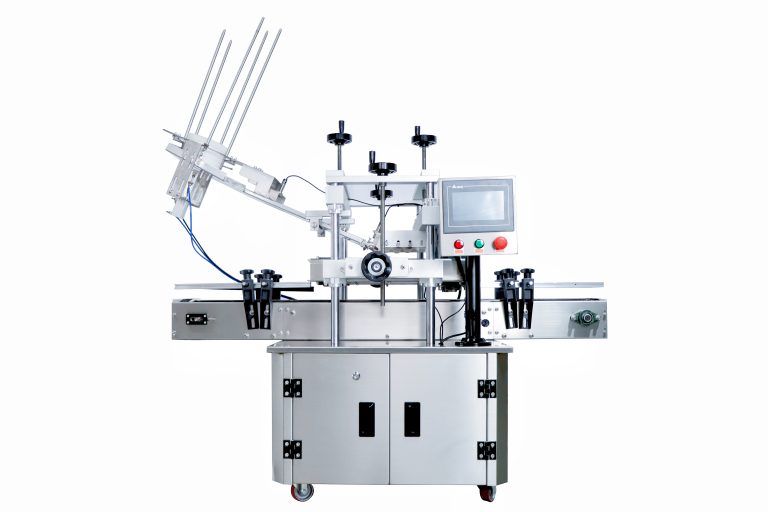

Exploring the Mechanics of Piston Fillers

Piston fillers are a popular choice for many industries due to their efficiency and reliability. These devices are used to fill containers with liquid or semi-liquid products, such as lotions, creams, and oils. In this article, we will explore the mechanics of piston fillers and how they work to provide accurate and consistent filling.

Piston fillers operate on a simple principle: a piston moves up and down within a cylinder to draw product into the cylinder and then dispense it into the container. The piston is typically made of stainless steel or other durable materials to withstand the rigors of continuous use. The cylinder is also made of high-quality materials to ensure a tight seal and prevent leakage.

One of the key advantages of piston fillers is their ability to provide precise filling volumes. The piston can be adjusted to control the amount of product dispensed, allowing for accurate filling of containers of various sizes. This level of control is essential for industries where consistency is crucial, such as pharmaceuticals and food production.

Piston fillers are also versatile and can handle a wide range of products, from thin liquids to thick pastes. The piston can be customized to accommodate different viscosities, ensuring that the product is dispensed smoothly and evenly. This flexibility makes piston fillers a popular choice for manufacturers who produce a variety of products.

Another benefit of piston fillers is their ease of maintenance. The simple design of these devices makes them easy to clean and maintain, reducing downtime and increasing productivity. Regular maintenance, such as lubricating the piston and cylinder, can help extend the life of the filler and ensure consistent performance.

In addition to their precision and versatility, piston fillers are also known for their speed. These devices can fill containers quickly and efficiently, allowing manufacturers to meet high production demands. The piston moves rapidly within the cylinder, minimizing the time it takes to fill each container.

Despite their many advantages, piston fillers do have some limitations. For example, they may not be suitable for products that contain particulates or solids, as these can clog the piston and cylinder. Additionally, piston fillers may not be the best choice for products that require a high level of sanitation, as the piston and cylinder can be difficult to clean thoroughly.

Overall, piston fillers are a reliable and efficient choice for many industries. Their precision, versatility, and speed make them ideal for filling a wide range of products with accuracy and consistency. By understanding the mechanics of piston fillers and how they work, manufacturers can make informed decisions about whether these devices are the right choice for their production needs.

In conclusion, piston fillers are a valuable tool for industries that require precise and efficient filling of containers. Their simple design, versatility, and speed make them a popular choice for manufacturers who value accuracy and consistency in their production processes. By investing in a high-quality piston filler and maintaining it properly, manufacturers can ensure reliable performance and increased productivity in their operations.