Benefits of Using Auger Bottle Powder Filling Machine

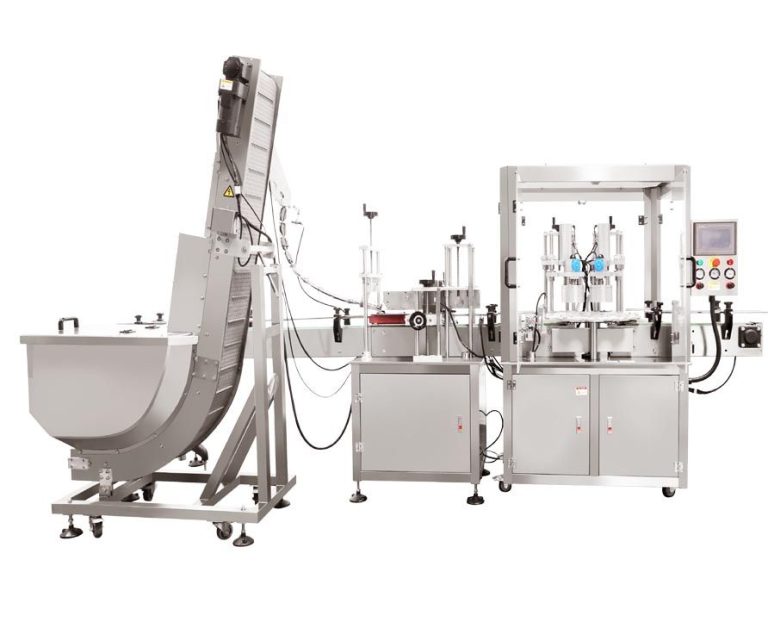

Auger bottle powder filling machines are a crucial piece of equipment in the packaging industry. These machines are designed to accurately fill bottles with various types of powders, such as spices, pharmaceuticals, and food supplements. The auger filling mechanism ensures precise and consistent filling, making it an ideal choice for businesses looking to improve their production efficiency and product quality.

One of the key benefits of using an auger bottle powder filling machine is its versatility. These machines can handle a wide range of bottle sizes and shapes, making them suitable for a variety of products. Whether you are filling small bottles for retail sale or larger containers for industrial use, an auger filling machine can meet your needs.

In addition to versatility, auger bottle powder filling machines offer high levels of accuracy. The auger mechanism measures out the exact amount of powder needed for each bottle, ensuring that every product meets the same quality standards. This level of precision is essential for businesses that require consistent product dosing and packaging.

Another advantage of using an auger bottle powder filling machine is its speed. These machines are capable of filling bottles at a much faster rate than manual filling methods, allowing businesses to increase their production output and meet customer demand more efficiently. This increased speed can also lead to cost savings, as fewer labor hours are required to fill bottles.

Auger bottle powder filling machines are also easy to operate and maintain. Most machines come with user-friendly controls that allow operators to adjust settings and monitor the filling process with ease. Additionally, these machines are designed to be durable and reliable, reducing the risk of downtime and costly repairs.

Furthermore, auger bottle powder filling machines are hygienic and compliant with industry regulations. These machines are typically made from stainless steel, which is easy to clean and sanitize, ensuring that products remain free from contamination. Additionally, auger filling machines can be equipped with features such as dust extraction systems to minimize powder spillage and maintain a clean working environment.

Overall, the benefits of using an auger bottle powder filling machine are clear. From increased versatility and accuracy to improved speed and ease of operation, these machines offer a range of advantages for businesses looking to streamline their packaging processes. By investing in an auger filling machine, companies can enhance their production efficiency, product quality, and overall profitability.

In conclusion, auger bottle powder filling machines are a valuable asset for businesses in the packaging industry. With their versatility, accuracy, speed, and ease of operation, these machines offer a range of benefits that can help companies improve their production processes and meet customer demand more effectively. Whether you are filling bottles with spices, pharmaceuticals, or food supplements, an auger filling machine is a reliable and efficient solution for your packaging needs.