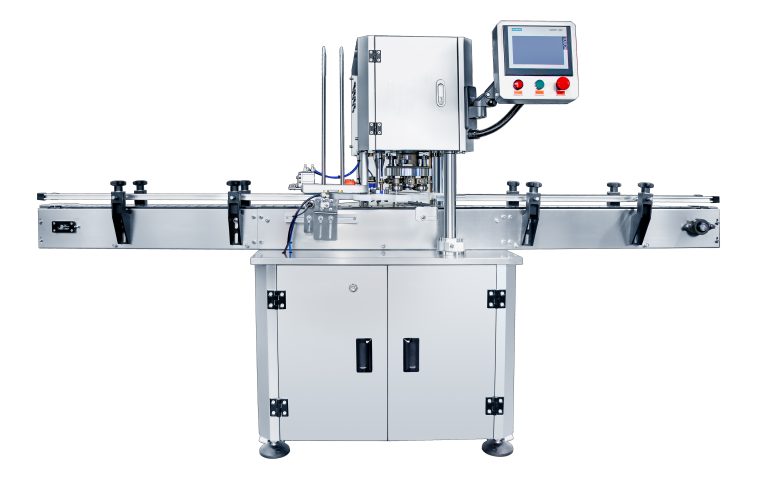

The Automatic Double Sides Labeling Machine comes equipped with a host of innovative features that set it apart in the world of labeling technology.

One of the standout features is its advanced sensor system. This enables precise detection of the product’s position and size, ensuring that labels are accurately applied to both sides without any misalignment or waste.

The machine’s customizable label application settings are highly innovative. It allows for adjustments in label size, shape, and orientation, accommodating a wide variety of products and label designs.

The high-speed operation is another remarkable feature. It can label a large number of products in a short period, significantly increasing productivity without sacrificing quality.

The intelligent control interface is user-friendly and intuitive. Operators can easily monitor and adjust parameters, making the labeling process smooth and hassle-free.

The automatic label feeding and cutting system ensures a continuous and seamless workflow. It reduces the need for frequent manual intervention, saving time and effort.

The machine also incorporates a self-diagnosis and error alert system. This helps identify and address any issues promptly, minimizing downtime and maximizing operational efficiency.

The compatibility with different types of labels, including adhesive labels and shrink sleeves, adds to its versatility and practicality.

In summary, the Automatic Double Sides Labeling Machine’s innovative features make it a cutting-edge solution for efficient and accurate labeling in various industries.