Table of Contents

Benefits of Using a Fully Automatic Masala Powder Filling Machine

Masala powder is an essential ingredient in Indian cuisine, adding flavor and aroma to dishes. As the demand for masala powder continues to rise, manufacturers are constantly looking for ways to increase efficiency and productivity in their production processes. One solution that has gained popularity in recent years is the use of fully automatic masala powder filling machines.

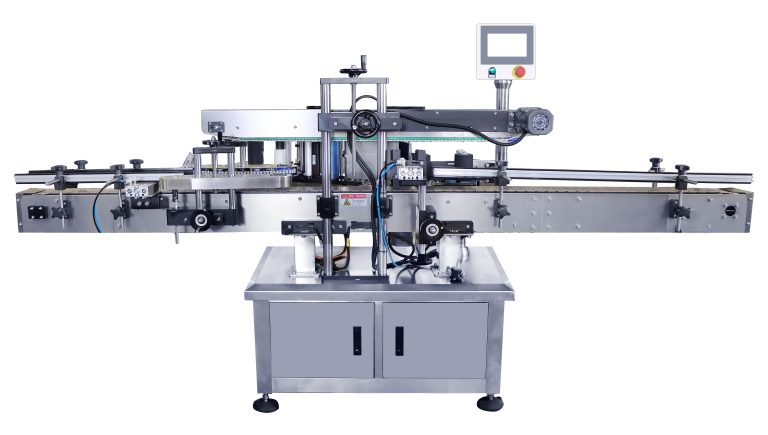

These machines are designed to accurately fill and package masala powder into containers with minimal human intervention. By automating the filling process, manufacturers can significantly increase their output while maintaining consistency and quality in their products. In this article, we will explore the benefits of using a fully automatic masala powder filling machine in a manufacturing setting.

One of the key benefits of using a fully automatic masala powder filling machine is the increase in production efficiency. These machines are capable of filling a large number of containers in a short amount of time, reducing the need for manual labor and streamlining the production process. This not only saves time but also allows manufacturers to meet the growing demand for masala powder in a timely manner.

In addition to improving efficiency, fully automatic masala powder filling machines also help to reduce the risk of human error. Manual filling processes are prone to inconsistencies and inaccuracies, which can affect the quality of the final product. By automating the filling process, manufacturers can ensure that each container is filled with the exact amount of masala powder, resulting in a consistent and high-quality product every time.

Furthermore, fully automatic masala powder filling machines are designed to be easy to operate and maintain. Once the machine is set up and calibrated, it can run continuously without the need for constant supervision. This allows manufacturers to focus on other aspects of their production process, knowing that the filling machine is operating efficiently and accurately.

Another benefit of using a fully automatic masala powder filling machine is the reduction in product waste. Manual filling processes can result in spillage and overfilling, leading to unnecessary waste of masala powder. By using a fully automatic filling machine, manufacturers can minimize product waste and maximize their production output, ultimately saving time and money in the long run.

Additionally, fully automatic masala powder filling machines are versatile and can be customized to meet the specific needs of different manufacturers. Whether filling small containers for retail sale or large containers for bulk packaging, these machines can be adjusted to accommodate various container sizes and filling requirements. This flexibility allows manufacturers to adapt to changing market demands and expand their product offerings without investing in additional equipment.

In conclusion, the benefits of using a fully automatic masala powder filling machine in a manufacturing setting are clear. From increased production efficiency and reduced human error to easy operation and maintenance, these machines offer a range of advantages that can help manufacturers improve their production processes and meet the growing demand for masala powder. By investing in a fully automatic filling machine, manufacturers can streamline their operations, increase their output, and ultimately enhance the quality of their products.

How to Choose the Right Fully Automatic Masala Powder Filling Machine for Your Business

In the food industry, efficiency and accuracy are key factors in ensuring the success of a business. When it comes to packaging spices and masala powders, having the right equipment can make a significant difference in the overall production process. Fully automatic masala powder filling machines are designed to streamline the packaging process, increase productivity, and reduce human error. However, with so many options available in the market, choosing the right machine for your business can be a daunting task.

One of the first things to consider when selecting a fully automatic masala powder filling machine is the production capacity of your business. Different machines are designed to handle varying levels of production, so it is important to choose a machine that can meet your specific needs. Whether you are a small-scale producer or a large-scale manufacturer, there is a machine available to suit your requirements.

Another important factor to consider is the type of masala powder you will be packaging. Some machines are specifically designed to handle fine powders, while others are better suited for coarser blends. It is essential to choose a machine that is compatible with the type of masala powder you will be packaging to ensure smooth operation and prevent clogging or other issues.

Additionally, consider the packaging material you will be using. Fully automatic masala powder filling machines come in different configurations to accommodate various types of packaging, such as pouches, bottles, or jars. Make sure to choose a machine that is compatible with the packaging material you will be using to avoid any compatibility issues.

When selecting a fully automatic masala powder filling machine, it is also important to consider the level of automation you require. Some machines come with advanced features such as automatic weighing, filling, and sealing, while others may require manual intervention at certain stages of the packaging process. Determine the level of automation that best suits your business needs and choose a machine accordingly.

Furthermore, consider the space available in your production facility. Fully automatic masala powder filling machines come in different sizes and configurations, so it is important to choose a machine that fits within your available space. Measure the dimensions of the machine and ensure that it can be easily integrated into your existing production line.

Lastly, consider the reputation and reliability of the manufacturer when choosing a fully automatic masala powder filling machine. Look for a manufacturer with a proven track record of producing high-quality machines that are durable and reliable. Read customer reviews and testimonials to get an idea of the machine’s performance and reliability in real-world applications.

In conclusion, choosing the right fully automatic masala powder filling machine for your business is a crucial decision that can impact the efficiency and productivity of your production process. Consider factors such as production capacity, type of masala powder, packaging material, level of automation, available space, and manufacturer reputation when making your decision. By carefully evaluating these factors, you can select a machine that meets your specific needs and helps you achieve success in the competitive food industry.