Table of Contents

Benefits of Using Fully Auto Paper Composite Can Seamer

In the world of packaging, efficiency and sustainability are becoming increasingly important factors for businesses to consider. One innovative solution that addresses both of these concerns is the fully auto paper composite can seamer. This cutting-edge technology offers a range of benefits for companies looking to streamline their packaging processes while also reducing their environmental impact.

One of the key advantages of using a fully auto paper composite can seamer is its ability to increase production efficiency. By automating the process of sealing paper composite cans, this technology can significantly reduce the time and labor required to package products. This means that companies can increase their output without having to hire additional staff or invest in costly manual labor.

Furthermore, the fully auto paper composite can seamer is designed to be user-friendly and easy to operate. This means that companies can quickly train their employees to use the machine, reducing the need for specialized skills or extensive training. This not only saves time and money but also ensures that the packaging process runs smoothly and efficiently.

In addition to improving production efficiency, the fully auto paper composite can seamer also offers environmental benefits. Paper composite cans are a sustainable alternative to traditional packaging materials such as plastic or metal. They are made from a combination of paper and other natural fibers, making them biodegradable and recyclable. By using paper composite cans, companies can reduce their carbon footprint and minimize their impact on the environment.

Furthermore, the fully auto paper composite can seamer is designed to minimize waste during the packaging process. By accurately sealing cans with precision and consistency, this technology helps to reduce the amount of product that is wasted due to improper sealing or packaging errors. This not only saves companies money but also helps to reduce their environmental impact by minimizing the amount of product that ends up in landfills.

Overall, the fully auto paper composite can seamer offers a range of benefits for companies looking to improve their packaging processes. From increasing production efficiency to reducing environmental impact, this technology is a valuable asset for businesses looking to stay ahead in an increasingly competitive market. By investing in a fully auto paper composite can seamer, companies can streamline their packaging processes, reduce waste, and demonstrate their commitment to sustainability.

Step-by-Step Guide on Operating a Fully Auto Paper Composite Can Seamer

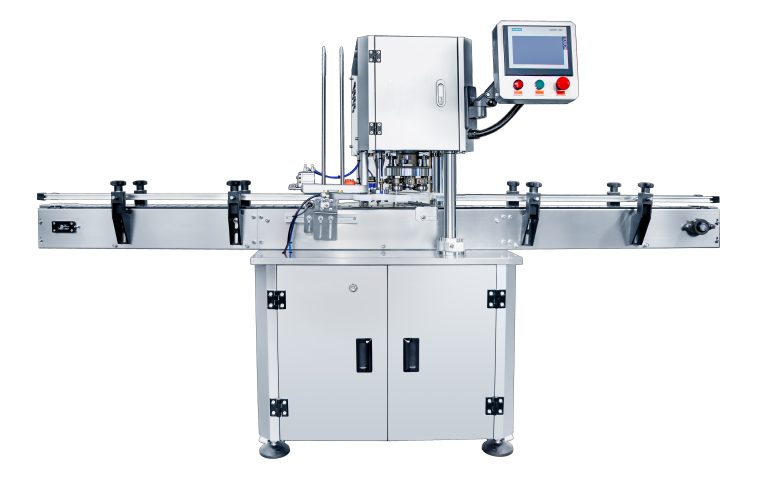

A fully auto paper composite can seamer is a sophisticated piece of machinery that is used to seal cans made from paper composite materials. This type of seamer is designed to automate the process of sealing cans, making it faster and more efficient than manual sealing methods. In this article, we will provide a step-by-step guide on how to operate a fully auto paper composite can seamer.

First and foremost, it is important to ensure that the can seamer is properly set up and calibrated before use. This includes making sure that the machine is clean and free of any debris, as well as checking that all the components are in good working order. Once the machine is ready to go, the next step is to load the cans into the seamer.

To do this, simply place the cans onto the conveyor belt of the seamer, making sure that they are evenly spaced and aligned properly. The machine will then automatically feed the cans into the seaming station, where the sealing process will take place. It is important to note that the seamer is equipped with sensors that will detect any misaligned or damaged cans, and will automatically reject them from the line.

Once the cans are in position, the seaming process can begin. The machine will use a combination of pressure and heat to seal the cans, ensuring that they are securely closed and airtight. The entire process is automated, meaning that there is minimal manual intervention required. This not only speeds up the sealing process but also reduces the risk of human error.

As the cans are sealed, they will be automatically discharged from the seamer and onto a conveyor belt for further processing. At this point, it is important to inspect the sealed cans to ensure that they are properly sealed and free of any defects. Any cans that do not meet the quality standards should be removed from the line and reprocessed.

Once the cans have been inspected and approved, they can be sent off for labeling and packaging. The fully auto paper composite can seamer is capable of sealing a large number of cans in a short amount of time, making it ideal for high-volume production environments. Additionally, the machine is designed to be easy to operate, with a user-friendly interface that allows operators to monitor the sealing process and make any necessary adjustments.

In conclusion, a fully auto paper composite can seamer is a valuable piece of equipment for sealing cans made from paper composite materials. By following the step-by-step guide outlined in this article, operators can ensure that the seamer is operated efficiently and effectively. With its automated sealing process and high-speed capabilities, the fully auto paper composite can seamer is a must-have for any production facility looking to streamline their can sealing operations.