It seems we can’t find what you’re looking for. Perhaps searching can help.

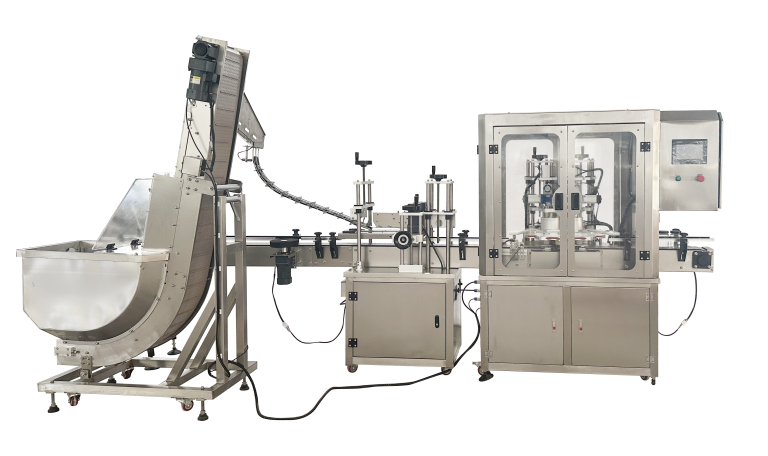

Glass bottle vacuum screw capping machine for canned fruit

Benefits of Using a Glass Bottle Vacuum Screw Capping Machine for Canned Fruit Glass bottle vacuum screw capping machines are essential equipment for the food industry, especially for canning fruits. These machines offer numerous benefits that can help improve the efficiency and quality of the canning process. In this article,…