Table of Contents

Benefits of Using Semi Auto Vacuum Can Seaming Machine for Milk Powder Packaging

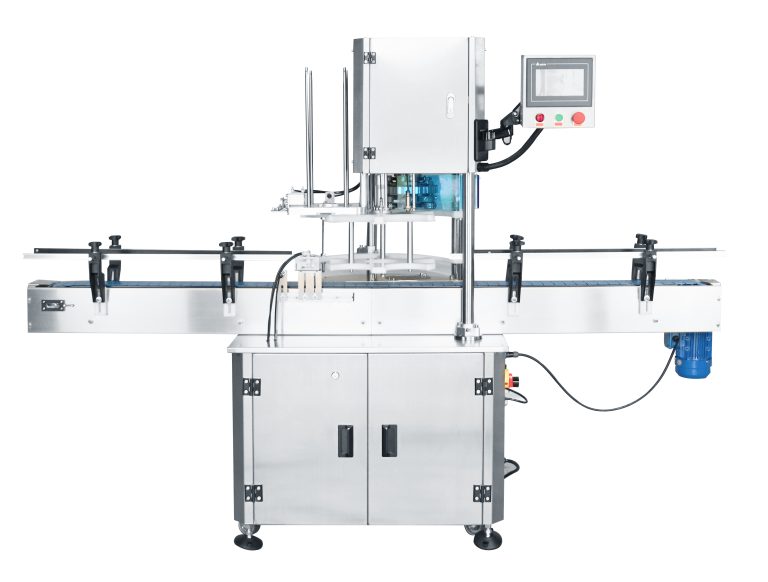

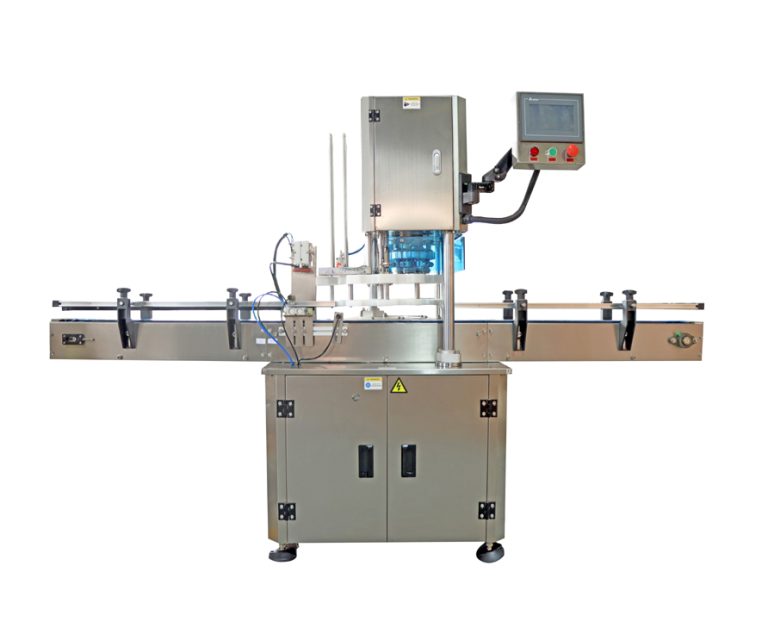

In the food packaging industry, efficiency and precision are key factors in ensuring the quality and safety of products. One of the essential machines used in the packaging process is the can seaming machine, which is responsible for sealing cans to protect the contents inside. When it comes to packaging milk powder, a semi-auto vacuum can seaming machine is a popular choice due to its numerous benefits.

One of the primary advantages of using a semi-auto vacuum can seaming machine for milk powder packaging is its ability to create a tight and secure seal. This is crucial in preventing contamination and spoilage of the product, ensuring that it remains fresh and safe for consumption. The vacuum sealing process removes excess air from the can, creating a vacuum that helps preserve the quality of the milk powder for a longer period.

Furthermore, the semi-auto vacuum can seaming machine is designed to handle a wide range of can sizes, making it versatile and adaptable to different packaging requirements. This flexibility allows manufacturers to efficiently package milk powder in various can sizes without the need for multiple machines, saving time and resources in the production process.

Another benefit of using a semi-auto vacuum can seaming machine is its user-friendly design, which makes it easy to operate and maintain. The machine is equipped with intuitive controls and settings that can be easily adjusted to meet specific packaging needs. This user-friendly interface reduces the risk of errors and ensures consistent and accurate sealing of cans, resulting in a high-quality finished product.

In addition to its ease of use, the semi-auto vacuum can seaming machine is also known for its durability and reliability. Built with high-quality materials and components, the machine is designed to withstand the rigors of continuous use in a production environment. This reliability ensures that manufacturers can depend on the machine to consistently deliver efficient and precise sealing of milk powder cans, minimizing downtime and maximizing productivity.

Furthermore, the semi-auto vacuum can seaming machine is cost-effective in the long run, as it helps reduce labor costs and increase production efficiency. By automating the can sealing process, manufacturers can streamline their operations and achieve higher output with fewer resources. This increased efficiency not only saves time and money but also improves overall product quality and consistency.

Overall, the benefits of using a semi-auto vacuum can seaming machine for milk powder packaging are clear. From its ability to create a tight and secure seal to its versatility, user-friendly design, durability, and cost-effectiveness, this machine offers numerous advantages that can help manufacturers improve their packaging processes and deliver high-quality products to consumers. By investing in a semi-auto vacuum can seaming machine, manufacturers can enhance their production capabilities and ensure the safety and freshness of their milk powder products.

Step-by-Step Guide on How to Operate a Semi Auto Vacuum Can Seaming Machine

A semi auto vacuum can seaming machine is a crucial piece of equipment for packaging milk powder cans efficiently and effectively. This machine is designed to seal cans with precision and consistency, ensuring that the product inside remains fresh and protected from external contaminants. Operating a semi auto vacuum can seaming machine may seem daunting at first, but with the right knowledge and guidance, it can be a straightforward process.

To begin operating a semi auto vacuum can seaming machine, it is essential to first familiarize yourself with the machine’s components and functions. This includes understanding how to adjust the can seaming rollers, set the appropriate vacuum pressure, and control the speed of the machine. By taking the time to learn about these key features, you can ensure that the machine operates smoothly and efficiently.

Once you have a good understanding of the machine’s components, the next step is to prepare the milk powder cans for sealing. This involves placing the cans onto the machine’s conveyor belt and ensuring that they are properly aligned for the seaming process. It is important to check that the cans are clean and free from any debris that could affect the sealing process.

After the cans are in position, it is time to start the machine and begin the seaming process. The machine will automatically seal the cans using a combination of vacuum pressure and mechanical rollers. It is important to monitor the machine closely during this process to ensure that the cans are being sealed correctly and that there are no issues with the sealing mechanism.

As the machine seals the cans, it is important to keep an eye on the vacuum pressure and adjust it as needed. The vacuum pressure plays a crucial role in ensuring that the cans are sealed tightly and that the product inside remains fresh. By monitoring and adjusting the vacuum pressure, you can ensure that the cans are sealed to the desired level of tightness.

Once the seaming process is complete, it is important to inspect the sealed cans to ensure that they meet the required quality standards. This includes checking for any leaks or imperfections in the seals, as well as ensuring that the cans are properly labeled and ready for distribution. By conducting a thorough inspection of the sealed cans, you can ensure that the product is safe and ready for sale.

In conclusion, operating a semi auto vacuum can seaming machine for milk powder cans is a straightforward process that requires attention to detail and precision. By familiarizing yourself with the machine’s components and functions, preparing the cans properly, and monitoring the seaming process closely, you can ensure that the cans are sealed correctly and that the product inside remains fresh and protected. With the right knowledge and guidance, you can operate a semi auto vacuum can seaming machine with confidence and efficiency.

Maintenance Tips for Ensuring Longevity and Efficiency of Semi Auto Vacuum Can Seaming Machine

In the food packaging industry, semi auto vacuum can seaming machines play a crucial role in ensuring the quality and safety of products such as milk powder. These machines are designed to seal cans tightly to prevent contamination and spoilage, making them an essential piece of equipment for any food processing facility. To ensure the longevity and efficiency of a semi auto vacuum can seaming machine, proper maintenance is key.

One of the most important maintenance tasks for a semi auto vacuum can seaming machine is regular cleaning. Over time, dust, debris, and food particles can build up on the machine’s components, leading to decreased performance and potential breakdowns. To prevent this, it is essential to clean the machine thoroughly after each use. This includes removing any leftover product from the can seaming area, wiping down the machine with a damp cloth, and using a brush to clean hard-to-reach areas.

In addition to regular cleaning, it is also important to inspect the machine for any signs of wear and tear. This includes checking for loose or damaged parts, worn seals, and any other issues that could affect the machine’s performance. If any problems are detected, they should be addressed promptly to prevent further damage and ensure the machine continues to operate efficiently.

Another important maintenance task for a semi auto vacuum can seaming machine is lubrication. Proper lubrication helps reduce friction between moving parts, preventing premature wear and extending the machine’s lifespan. It is important to use the correct type of lubricant for the machine’s components and to apply it according to the manufacturer’s recommendations. Over-lubrication can be just as damaging as under-lubrication, so it is important to follow the guidelines carefully.

Regular calibration is also essential for maintaining the efficiency of a semi auto vacuum can seaming machine. Calibration ensures that the machine is operating at the correct settings, which is crucial for achieving a tight seal on cans. It is recommended to calibrate the machine regularly, especially after any repairs or adjustments have been made. This will help ensure that the machine continues to produce high-quality seals and prevent any issues with product integrity.

In addition to these maintenance tasks, it is important to train operators on how to use the semi auto vacuum can seaming machine properly. Proper training can help prevent operator error, which can lead to damage to the machine or poor-quality seals on cans. Operators should be familiar with the machine’s operation manual and safety guidelines, as well as any specific instructions for the type of product being sealed.

By following these maintenance tips, food processing facilities can ensure the longevity and efficiency of their semi auto vacuum can seaming machines. Regular cleaning, inspection, lubrication, calibration, and operator training are all essential for keeping these machines in top condition. With proper maintenance, food processing facilities can continue to produce high-quality products safely and efficiently.

-768x622.jpg)