Benefits of Using a Dual Head Mayonnaise Glass Jar Vacuum Capping Machine

Mayonnaise is a popular condiment that is used in a variety of dishes. Whether it’s spread on a sandwich or used as a base for a salad dressing, mayonnaise adds a creamy and tangy flavor to any meal. As a result, many food manufacturers and restaurants rely on mayonnaise to enhance the taste of their products. However, one challenge that they often face is ensuring that the mayonnaise jars are properly sealed to maintain freshness and prevent spoilage. This is where a dual head mayonnaise glass jar vacuum capping machine comes in handy.

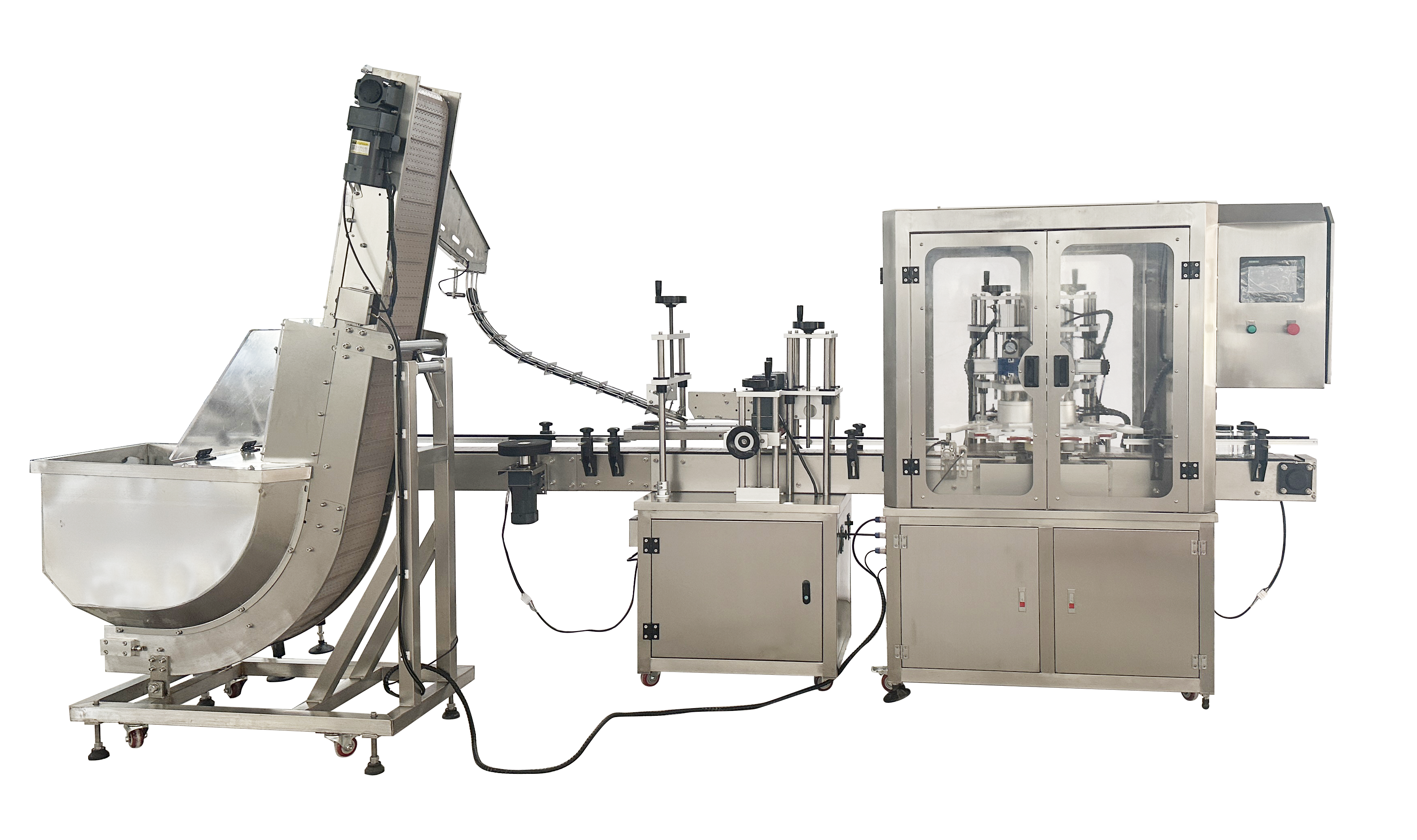

One of the main benefits of using a dual head mayonnaise glass jar vacuum capping machine is its efficiency. With two capping heads, this machine can cap two jars simultaneously, saving time and increasing productivity. This is especially important for large-scale food manufacturers who need to cap a high volume of jars in a short amount of time. By using a dual head machine, they can significantly speed up the capping process and meet their production targets more efficiently.

Another advantage of using a dual head mayonnaise glass jar vacuum capping machine is its ability to create a vacuum seal. Vacuum sealing is a method of packaging that removes air from the jar, creating a tight seal that helps to preserve the freshness and quality of the mayonnaise. This is particularly important for mayonnaise, as exposure to air can cause it to spoil quickly. By using a dual head machine, food manufacturers can ensure that each jar is properly sealed, reducing the risk of spoilage and extending the shelf life of their products.

In addition to efficiency and vacuum sealing, a dual head mayonnaise glass jar vacuum capping machine also offers versatility. This machine is designed to cap a wide range of jar sizes, allowing food manufacturers to use it for different packaging needs. Whether they are capping small jars for individual servings or larger jars for bulk orders, a dual head machine can accommodate various sizes, making it a versatile tool for any food production facility.

Furthermore, a dual head mayonnaise glass jar vacuum capping machine is easy to operate and maintain. It is equipped with user-friendly controls and features that make it simple to set up and adjust according to specific requirements. Additionally, the machine is built with durable materials that are easy to clean and maintain, ensuring its longevity and reliability in the production line.

Lastly, investing in a dual head mayonnaise glass jar vacuum capping machine can lead to cost savings in the long run. By automating the capping process, food manufacturers can reduce the need for manual labor, which can be costly and time-consuming. Additionally, the machine’s efficiency and ability to create a vacuum seal can minimize product waste and spoilage, resulting in higher profits for the business.

In conclusion, a dual head mayonnaise glass jar vacuum capping machine offers numerous benefits for food manufacturers and restaurants. Its efficiency, vacuum sealing capability, versatility, ease of operation, and cost savings make it an invaluable tool in the production line. By investing in this machine, businesses can ensure that their mayonnaise jars are properly sealed, maintaining the freshness and quality of their products.