Table of Contents

Benefits of Using Automatic Dual Head Screwing Capping Machine for Bottle

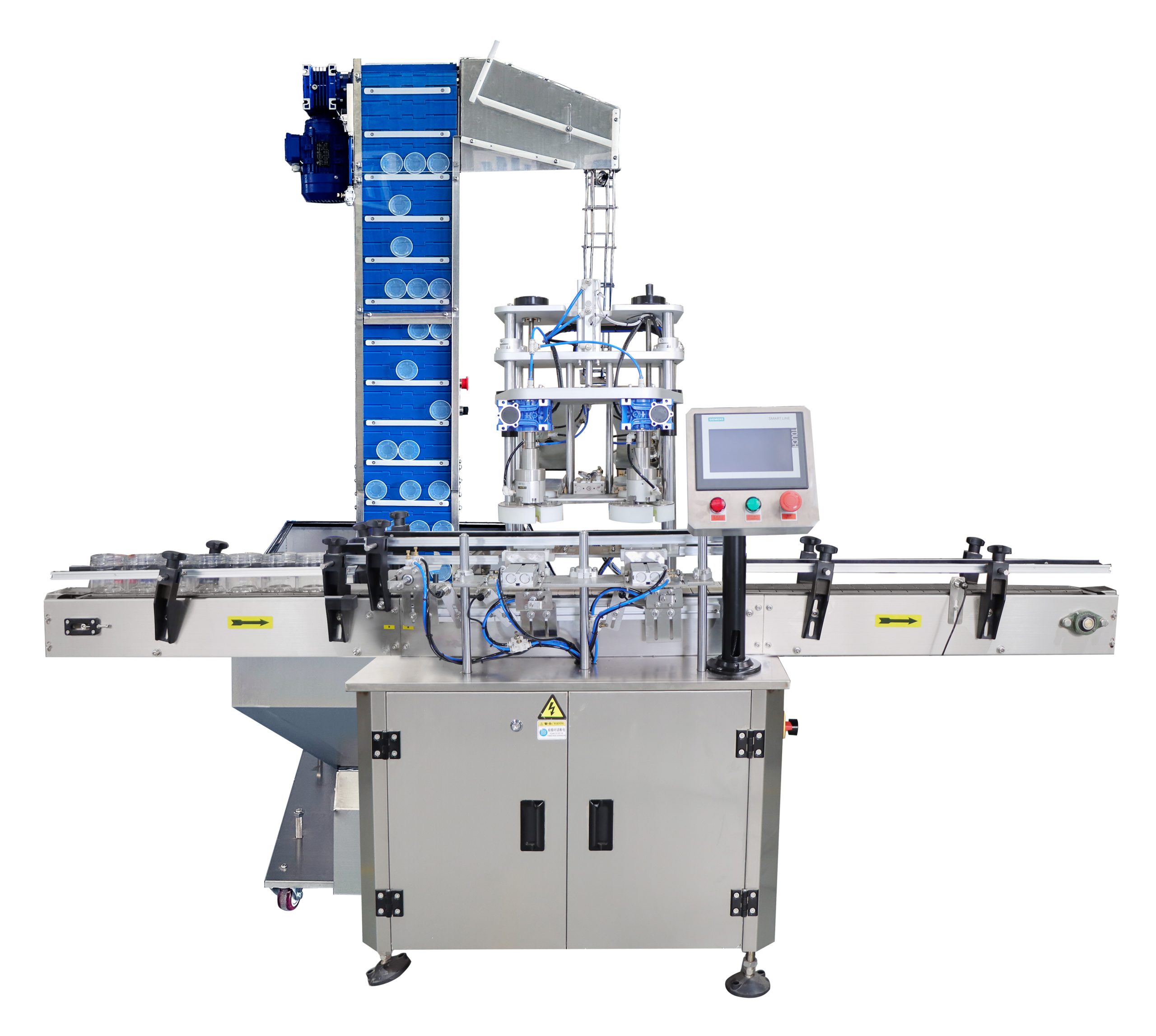

Automatic dual head screwing capping machines have revolutionized the packaging industry by providing a fast and efficient way to cap bottles. These machines are designed to handle a wide range of bottle sizes and shapes, making them versatile and adaptable to various production needs. In this article, we will explore the benefits of using an automatic dual head screwing capping machine for bottles.

One of the key benefits of using an automatic dual head screwing capping machine is its speed and efficiency. These machines are capable of capping hundreds of bottles per minute, significantly increasing production output and reducing labor costs. By automating the capping process, companies can streamline their production line and improve overall efficiency.

In addition to speed, automatic dual head screwing capping machines also ensure consistent and precise capping results. The dual head design allows for simultaneous capping of two bottles, ensuring that each bottle is capped with the same level of tightness and accuracy. This consistency is crucial for maintaining product quality and preventing leaks or contamination.

Another benefit of using an automatic dual head screwing capping machine is its versatility. These machines can be easily adjusted to accommodate different bottle sizes and shapes, making them suitable for a wide range of products. Whether you are capping small vials or large containers, an automatic dual head screwing capping machine can handle the job with ease.

Furthermore, automatic dual head screwing capping machines are user-friendly and easy to operate. With intuitive controls and minimal setup requirements, operators can quickly learn how to use these machines and start capping bottles in no time. This ease of use reduces training time and allows companies to maximize their production efficiency.

In addition to their speed, precision, versatility, and user-friendly design, automatic dual head screwing capping machines also offer a cost-effective solution for bottle capping. By automating the capping process, companies can reduce the need for manual labor and minimize the risk of human error. This not only saves time and money but also improves overall product quality and consistency.

Overall, the benefits of using an automatic dual head screwing capping machine for bottles are clear. These machines offer a fast, efficient, and precise way to cap bottles, while also providing versatility, user-friendliness, and cost-effectiveness. Whether you are a small startup or a large production facility, investing in an automatic dual head screwing capping machine can help you streamline your production process and improve your bottom line.

How to Choose the Right Automatic Dual Head Screwing Capping Machine for Your Bottling Line

When it comes to bottling products, having the right equipment is essential to ensure efficiency and consistency in the packaging process. One key piece of equipment that can greatly improve the speed and accuracy of your bottling line is an automatic dual head screwing capping machine. This machine is designed to automatically cap bottles with screw caps, making the process much faster and more reliable than manual capping.

There are several factors to consider when choosing the right automatic dual head screwing capping machine for your bottling line. One of the most important factors to consider is the speed of the machine. The speed of the machine will determine how quickly bottles can be capped, which can have a significant impact on the overall efficiency of your bottling line. It is important to choose a machine that can cap bottles at a speed that matches the output of your bottling line.

Another important factor to consider is the size and shape of the bottles that will be capped. Different machines are designed to cap different sizes and shapes of bottles, so it is important to choose a machine that is compatible with the bottles you will be using. Some machines are adjustable and can accommodate a wide range of bottle sizes, while others are designed for specific bottle sizes.

In addition to speed and compatibility with bottle sizes, it is also important to consider the reliability and durability of the machine. A reliable machine will minimize downtime and maintenance costs, while a durable machine will last for many years without needing to be replaced. It is important to choose a machine from a reputable manufacturer that has a track record of producing high-quality equipment.

One feature to look for in an automatic dual head screwing capping machine is the ability to adjust the torque of the caps. Different products may require different levels of torque to ensure a secure seal, so having the ability to adjust the torque settings on the machine can be very useful. This feature can help ensure that each bottle is capped correctly, regardless of the type of product being bottled.

Another important feature to consider is the ease of use of the machine. A user-friendly machine will be easier for operators to learn and use, which can help minimize training time and reduce the likelihood of errors during operation. Look for a machine that has intuitive controls and clear instructions for operation.

Finally, it is important to consider the cost of the machine. Automatic dual head screwing capping machines can vary widely in price, so it is important to choose a machine that fits within your budget while still meeting your needs in terms of speed, compatibility, reliability, and features.

In conclusion, choosing the right automatic dual head screwing capping machine for your bottling line is a crucial decision that can have a significant impact on the efficiency and effectiveness of your packaging process. By considering factors such as speed, compatibility with bottle sizes, reliability, torque adjustment, ease of use, and cost, you can select a machine that will help streamline your bottling operations and improve the overall quality of your products.

Maintenance Tips for Automatic Dual Head Screwing Capping Machine to Ensure Longevity

Automatic dual head screwing capping machines are essential equipment in the packaging industry, as they play a crucial role in sealing bottles securely. These machines are designed to streamline the capping process, increasing efficiency and productivity. However, like any other machinery, they require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tips for automatic dual head screwing capping machines is to keep them clean. Dust, dirt, and debris can accumulate on the machine’s components, leading to malfunctions and decreased efficiency. Regularly cleaning the machine with a soft cloth and mild detergent can help prevent these issues and prolong its lifespan.

In addition to cleaning, it is essential to lubricate the moving parts of the capping machine regularly. Lubrication helps reduce friction between components, preventing wear and tear and ensuring smooth operation. Be sure to use the appropriate lubricant recommended by the manufacturer to avoid damaging the machine.

Inspecting the machine for any signs of wear and tear is another crucial maintenance tip. Check for loose or damaged parts, such as belts, chains, and screws, and replace them as needed. Ignoring these issues can lead to more significant problems down the line, resulting in costly repairs and downtime.

Calibrating the machine regularly is also essential to maintain its accuracy and efficiency. Over time, the machine’s settings may drift, affecting the quality of the capping process. By calibrating the machine according to the manufacturer’s specifications, you can ensure consistent and reliable performance.

Another maintenance tip for automatic dual head screwing capping machines is to train your operators properly. Proper training can help prevent operator errors that can damage the machine or lead to inefficiencies. Make sure your operators understand how to operate the machine safely and efficiently to avoid unnecessary wear and tear.

Regularly inspecting and replacing the machine’s wear parts, such as seals and gaskets, is also crucial for maintaining its performance. These parts can deteriorate over time, leading to leaks and other issues. By replacing them proactively, you can prevent more significant problems and extend the machine’s lifespan.

Lastly, scheduling routine maintenance checks with a qualified technician can help identify potential issues before they escalate. A professional technician can inspect the machine thoroughly, identify any problems, and perform necessary repairs or adjustments. Regular maintenance checks can help prevent unexpected breakdowns and ensure the machine operates at its best.

In conclusion, proper maintenance is essential for ensuring the longevity and performance of automatic dual head screwing capping machines. By following these maintenance tips, you can keep your machine running smoothly and efficiently, reducing downtime and increasing productivity. Remember to clean, lubricate, inspect, calibrate, train operators, replace wear parts, and schedule routine maintenance checks to keep your capping machine in top condition.