Table of Contents

Introduction

In the highly competitive world of product packaging, achieving the perfect balance between product protection, shelf – life extension, and cost – effectiveness is crucial. Enter the semi – automatic vacuum nitrogen flushing seaming machine, a true secret weapon that has been revolutionizing the packaging industry. This remarkable piece of equipment combines several essential functions to ensure that products are packaged in the best possible way.

Unveiling the Machine’s Functions

Vacuuming: Removing the Enemy – Oxygen

The first step in the packaging process with this machine is vacuuming. Oxygen is the arch – enemy of many products, especially food items, pharmaceuticals, and electronics. In the food industry, oxygen can cause oxidation, leading to the spoilage of fats, the browning of fruits and vegetables, and the growth of aerobic bacteria. For pharmaceuticals, it can degrade active ingredients, reducing their effectiveness.

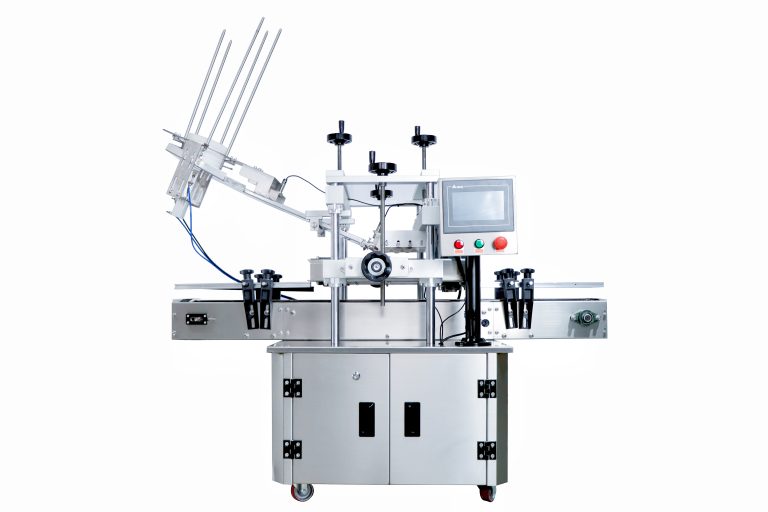

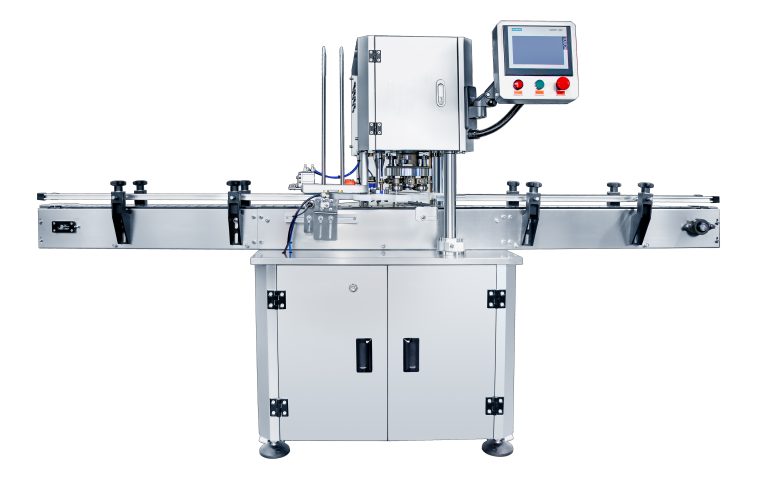

The semi – automatic vacuum nitrogen flushing seaming machine uses a powerful vacuum pump to suck out the air from the packaging container. By creating a low – pressure environment, it effectively removes the majority of oxygen present. This not only slows down the spoilage process but also helps to maintain the original quality of the product.

Nitrogen Flushing: Creating a Protective Shield

After the vacuuming process, nitrogen gas is introduced into the container. Nitrogen is an inert gas, which means it does not react with the product inside. It acts as a protective shield, replacing the removed oxygen. This is particularly important for products that are sensitive to oxygen.

In the case of food products, nitrogen flushing can prevent the growth of mold and bacteria, preserve the flavor and aroma, and maintain the nutritional value. For electronics, it can protect sensitive components from oxidation and corrosion. The machine allows for precise control of the nitrogen flushing process, ensuring that the right amount of nitrogen is introduced for optimal protection.

Seaming: Ensuring a Hermetic Seal

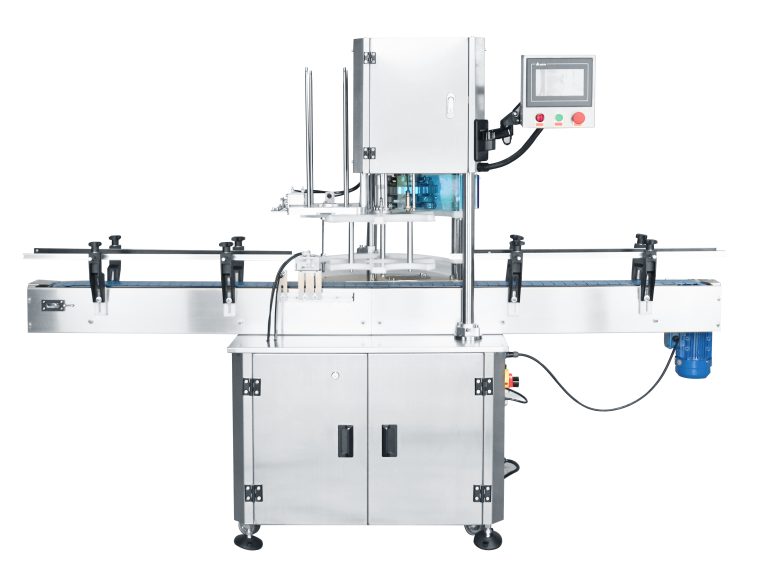

The final step in the process is seaming. Once the container is filled with nitrogen, the machine uses a set of seaming rollers to seal the lid onto the container. A proper seam is essential to maintain the vacuum and nitrogen environment inside the package. It prevents the entry of external air, moisture, and contaminants.

The semi – automatic nature of the seaming process allows for some manual intervention, which is beneficial for handling different types of containers and lids. Operators can ensure that the seaming is done correctly, resulting in a hermetic seal that keeps the product safe during storage and transportation.

Why It’s the Secret Weapon

Extended Shelf – Life

One of the most significant advantages of using this machine is the extended shelf – life it provides. By removing oxygen and replacing it with nitrogen, the machine can significantly slow down the degradation processes that occur in products. This means that products can be stored for longer periods without losing their quality. For example, a bag of coffee beans that would normally go stale in a few weeks can last for several months when packaged using this machine.

Cost – Effectiveness

Despite its advanced features, the semi – automatic vacuum nitrogen flushing seaming machine is a cost – effective solution for many businesses. It is more affordable than fully automatic machines, making it accessible to small and medium – sized enterprises. Additionally, the semi – automatic operation allows for greater flexibility in production volume. Businesses can adjust the production rate according to their needs, which helps to optimize costs.

Product Quality Preservation

The machine plays a crucial role in preserving the quality of products. Whether it’s the freshness of food, the potency of pharmaceuticals, or the functionality of electronics, the protective packaging created by the machine ensures that products reach the consumers in the best possible condition. This can lead to increased customer satisfaction and brand loyalty.

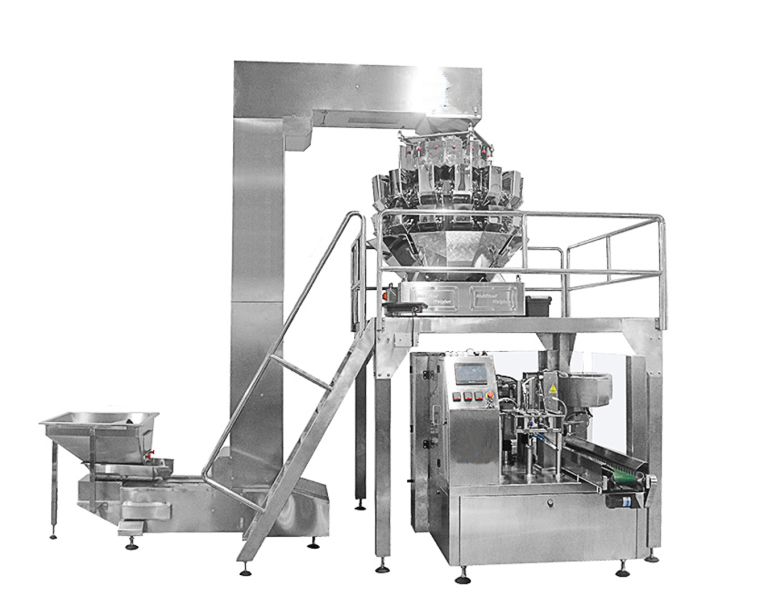

Versatility

The semi – automatic vacuum nitrogen flushing seaming machine is highly versatile. It can be used with a wide range of containers, including cans, jars, and bags. It can also handle different types of products, from food and beverages to chemicals and cosmetics. This versatility makes it a valuable asset for businesses in various industries.

Conclusion

In conclusion, the semi – automatic vacuum nitrogen flushing seaming machine is truly a secret weapon for perfect packaging. Its ability to vacuum, flush with nitrogen, and seam containers effectively provides numerous benefits, including extended shelf – life, cost – effectiveness, product quality preservation, and versatility. As the demand for high – quality, long – lasting products continues to grow, this machine will undoubtedly play an even more important role in the packaging industry.

What are the main components of a semi-automatic vacuum nitrogen flushing seaming machine?

How does the vacuum function in the semi-automatic vacuum nitrogen flushing seaming machine work?

Can the semi-automatic vacuum nitrogen flushing seaming machine be customized for specific packaging needs?