In the highly competitive world of can manufacturing, finding the edge that sets a business apart is crucial. Enter the automatic dual – head servo can seaming machine, a technological marvel that has been quietly revolutionizing the can seaming process. This machine is like a well – kept secret weapon, and it’s time to unveil its capabilities.

Table of Contents

Unmatched Speed and Productivity

The most obvious advantage of the automatic dual – head servo can seaming machine is its incredible speed. Traditional can seaming machines typically have a single head, which limits the number of cans they can seal in a given time. In contrast, the dual – head design of this machine allows it to work on two cans simultaneously.

This means that production rates can skyrocket. For example, in a large – scale food canning factory, the ability to double the seaming speed can translate into thousands more cans being produced each day. This increased productivity not only helps meet growing market demands but also allows manufacturers to take on larger orders and expand their business.

Precision Sealing for Quality Assurance

Quality is non – negotiable in the canning industry. A poorly sealed can can lead to spoilage, leakage, and a damaged reputation. The automatic dual – head servo can seaming machine addresses this concern with its advanced servo technology.

Servo motors provide precise control over the seaming process. They can adjust the seaming force, speed, and position with extreme accuracy, ensuring that each can is sealed perfectly. This precision is consistent across all cans, regardless of the production volume. Whether it’s a batch of a few hundred or thousands of cans, the quality of the seal remains top – notch.

Flexibility to Accommodate Various Can Sizes and Shapes

The canning industry produces a wide variety of cans, from small, round beverage cans to large, rectangular food containers. The automatic dual – head servo can seaming machine is designed to be highly flexible and can adapt to different can sizes and shapes.

With a simple adjustment of the machine’s settings, operators can switch between different can specifications. This eliminates the need for multiple seaming machines for different can types, saving both space and money. It also allows manufacturers to quickly respond to changes in customer demand and produce a diverse range of products on the same production line.

Reducing Labor and Operational Costs

In addition to its speed, precision, and flexibility, the automatic dual – head servo can seaming machine offers significant cost – saving benefits. The increased productivity means that fewer machines are needed to achieve the same output, reducing the initial investment in equipment.

Moreover, the machine’s automation reduces the need for a large workforce. Fewer operators are required to oversee the seaming process, which cuts down on labor costs. The high level of precision also minimizes the number of defective cans, reducing waste and the cost of raw materials.

Ease of Use and Maintenance

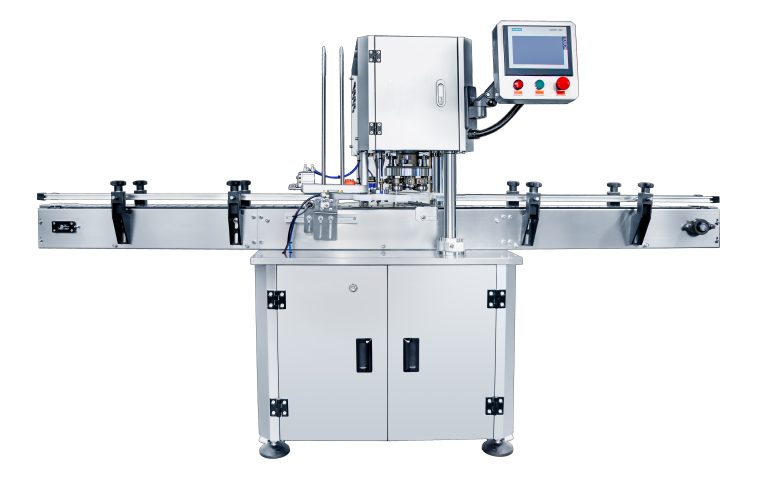

Despite its advanced technology, the automatic dual – head servo can seaming machine is designed to be user – friendly. It comes with an intuitive control panel that allows operators to easily set up the seaming parameters, monitor the production process, and troubleshoot any issues.

The machine’s modular design makes maintenance straightforward. Components can be easily accessed and replaced, minimizing downtime in case of a breakdown. Regular maintenance can be carried out quickly and efficiently, ensuring that the machine operates at its optimal level for a long time.

A Competitive Edge in the Market

In today’s global market, where consumers demand high – quality products at competitive prices, the automatic dual – head servo can seaming machine gives manufacturers a significant competitive edge. By increasing productivity, improving quality, and reducing costs, it allows companies to offer better – priced products without sacrificing quality.

It also enables manufacturers to be more responsive to market changes and customer demands. With the ability to produce a wide range of can sizes and shapes quickly and efficiently, they can stay ahead of the competition and capture a larger share of the market.

In conclusion, the automatic dual – head servo can seaming machine is truly a secret weapon in the canning industry. Its combination of speed, precision, flexibility, cost – savings, and ease of use makes it an invaluable asset for any can manufacturer. By revealing this hidden gem, we hope that more businesses will embrace this technology and unlock its full potential for success.