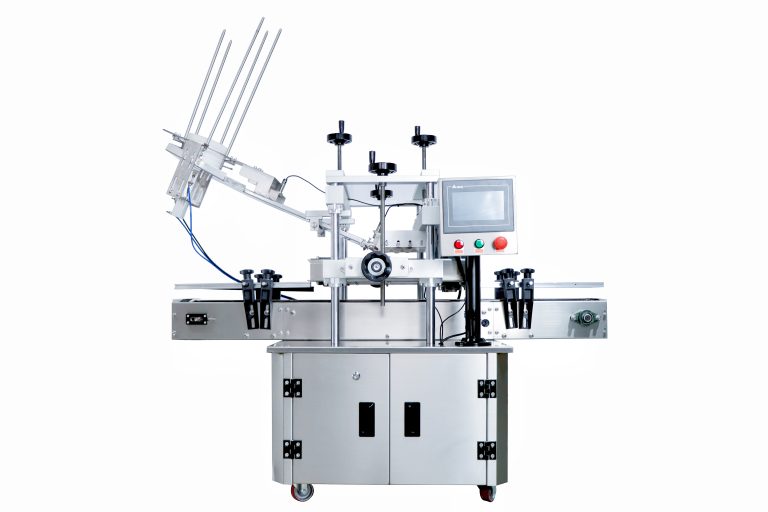

In the realm of tin can packaging, the double head servo tin can crimper machine is a remarkable innovation.

This advanced machine is specifically designed to provide efficient and precise crimping for tin cans. The double head configuration is a standout feature that significantly boosts productivity.

One of the key benefits of this machine is its servo technology. It ensures accurate and consistent crimping pressure, resulting in a secure and uniform seal every time. This is crucial for maintaining the integrity of the packaged contents and preventing leakage.

The high-speed operation of the double head design allows for a large number of tin cans to be processed in a short period. This is especially valuable for businesses with high production demands, as it helps meet deadlines and increase output.

The machine is also highly adaptable. It can handle different sizes and shapes of tin cans, offering flexibility to manufacturers dealing with a diverse range of products.

In terms of quality control, the double head servo tin can crimper machine often comes equipped with sensors and monitoring systems to detect any faults or deviations in the crimping process. This helps ensure that only properly crimped cans make it to the market.

Its user-friendly interface makes it easy for operators to control and adjust the settings, minimizing the learning curve and maximizing productivity.

Maintenance is relatively straightforward, with accessible components and clear servicing instructions. This helps to minimize downtime and keep the machine running smoothly.

Overall, the double head servo tin can crimper machine is a powerful tool that combines speed, accuracy, and flexibility to elevate the quality and efficiency of tin can packaging operations.

Stay tuned to our blogs for more in-depth looks at the latest advancements in packaging machinery!