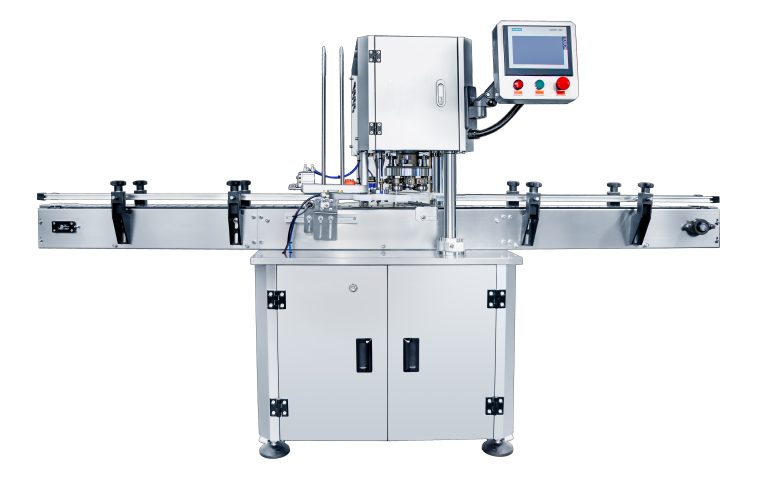

In the world of packaging, Automatic Vacuum Can Sealing Machines have brought about a revolutionary transformation. These machines have redefined the way products are packaged, offering numerous benefits and improvements.

One of the most significant ways they transform packaging is by enhancing the shelf life of products. By creating a vacuum seal within the can, these machines prevent the entry of air and moisture, which are the main causes of spoilage. This means products can stay fresh and usable for much longer periods, reducing waste and increasing customer satisfaction.

The quality and appearance of the packaging also undergo a remarkable change. The tight and consistent seal provided by automatic vacuum can sealing machines gives the packaging a professional and aesthetically pleasing look. It not only protects the contents but also makes the product more attractive on the shelves, enhancing its marketability.

Another aspect of transformation is the increased efficiency in the packaging process. These machines operate at high speeds, allowing for a large volume of cans to be sealed in a short time. This boosts productivity and helps businesses meet the demands of the market promptly.

They also contribute to improved safety and hygiene. The vacuum seal ensures that the contents are protected from external contaminants, maintaining the purity and integrity of the product. This is especially crucial in industries such as food and pharmaceuticals.

Furthermore, automatic vacuum can sealing machines offer flexibility in packaging options. They can handle various can sizes and materials, enabling businesses to adapt to different product requirements and market trends.

In conclusion, Automatic Vacuum Can Sealing Machines have had a profound impact on packaging. From extending shelf life and enhancing appearance to increasing efficiency and ensuring safety, they have become an indispensable tool for modern packaging operations, shaping the future of the industry.