In the highly competitive world of manufacturing, having the right equipment can make all the difference. An automatic vacuum capper for glass packaging is a game-changer that can bring numerous benefits to your production line.

Firstly, it ensures superior product quality. The vacuum sealing process provided by this capper helps to preserve the freshness, flavor, and integrity of the contents within the glass packaging. This means your customers will receive products that are at their best, enhancing your brand reputation.

Secondly, it boosts productivity. An automatic vacuum capper operates at a rapid pace, allowing you to package a large number of glass containers in a short time. This increased efficiency helps you meet tight deadlines and fulfill high-volume orders without compromising on quality.

It also reduces spoilage and waste. By creating a vacuum seal, the capper minimizes the risk of contamination and extends the shelf life of the products. This not only saves you money but also contributes to a more sustainable production process.

Furthermore, it offers consistent and reliable packaging. Every glass container is sealed with the same precision and tightness, reducing the chances of leaks or inconsistent seals that could lead to product recalls or customer dissatisfaction.

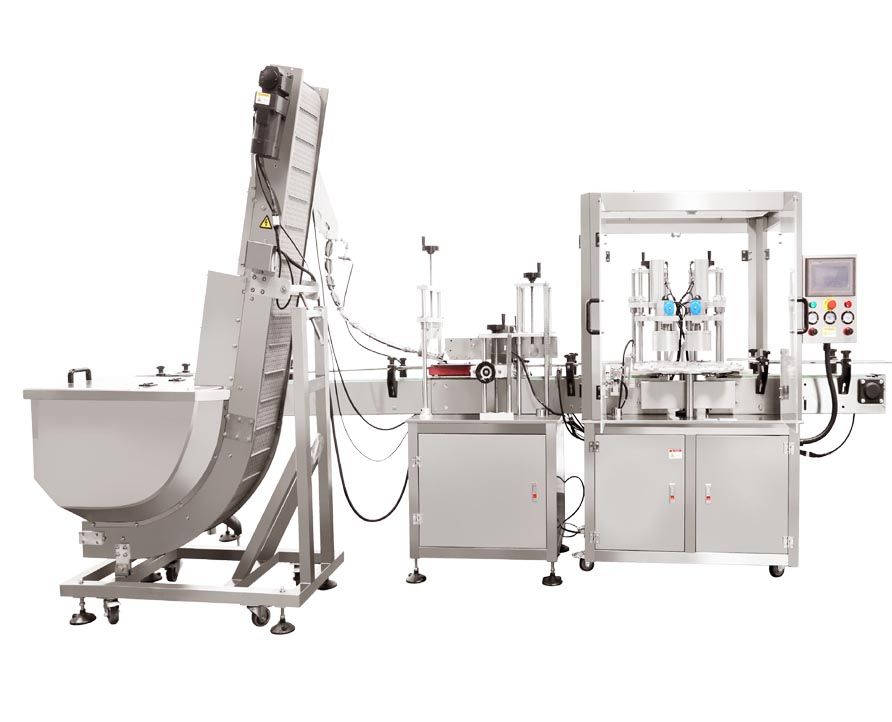

The automatic vacuum capper is also easy to integrate into your existing production line. Its user-friendly design and compatibility with other equipment make it a seamless addition that can streamline your overall operations.

In conclusion, an automatic vacuum capper for glass packaging is not just a nice-to-have but a necessary investment for your production line. It improves product quality, increases productivity, reduces waste, and ensures consistent packaging, giving you a competitive edge in the market.