Table of Contents

Benefits of Using a Dustproof Cap Capping Machine for Paper Can

In the manufacturing industry, efficiency and quality are key factors in ensuring the success of a business. One important aspect of production is the sealing of containers to protect the contents from external elements. When it comes to paper cans, using a dustproof cap capping machine can provide numerous benefits that can improve the overall production process.

One of the main advantages of using a dustproof cap capping machine for paper cans is the prevention of contamination. Dust and other particles can easily enter containers during the sealing process, compromising the quality of the product inside. By using a capping machine with a dustproof cap, manufacturers can ensure that their products remain clean and free from any external contaminants.

Additionally, a dustproof cap capping machine can help improve the overall efficiency of the production process. Manual capping can be time-consuming and labor-intensive, leading to slower production rates and increased costs. By automating the capping process with a machine, manufacturers can significantly increase their output and reduce the need for manual labor.

Furthermore, using a dustproof cap capping machine can also help improve the overall safety of the production environment. Manual capping can be a hazardous task, especially when dealing with sharp or heavy objects. By using a machine to cap paper cans, manufacturers can reduce the risk of injuries and create a safer working environment for their employees.

Another benefit of using a dustproof cap capping machine is the consistency and accuracy it provides. Manual capping can lead to variations in the tightness of the caps, which can affect the overall quality of the product. By using a machine, manufacturers can ensure that each cap is applied with the same level of precision, resulting in a more uniform and professional-looking finished product.

In addition to these benefits, a dustproof cap capping machine can also help reduce waste and improve sustainability. By preventing contamination and ensuring a tight seal on each container, manufacturers can reduce the likelihood of product spoilage and minimize the need for rework or disposal. This not only saves time and money but also helps to reduce the environmental impact of production.

Overall, the use of a dustproof cap capping machine for paper cans offers numerous benefits that can help improve the efficiency, quality, and safety of the production process. By investing in this technology, manufacturers can streamline their operations, protect their products, and create a more sustainable manufacturing environment. With these advantages in mind, it is clear that a dustproof cap capping machine is a valuable asset for any business looking to enhance their production capabilities.

How to Choose the Right Dustproof Cap Capping Machine for Paper Can

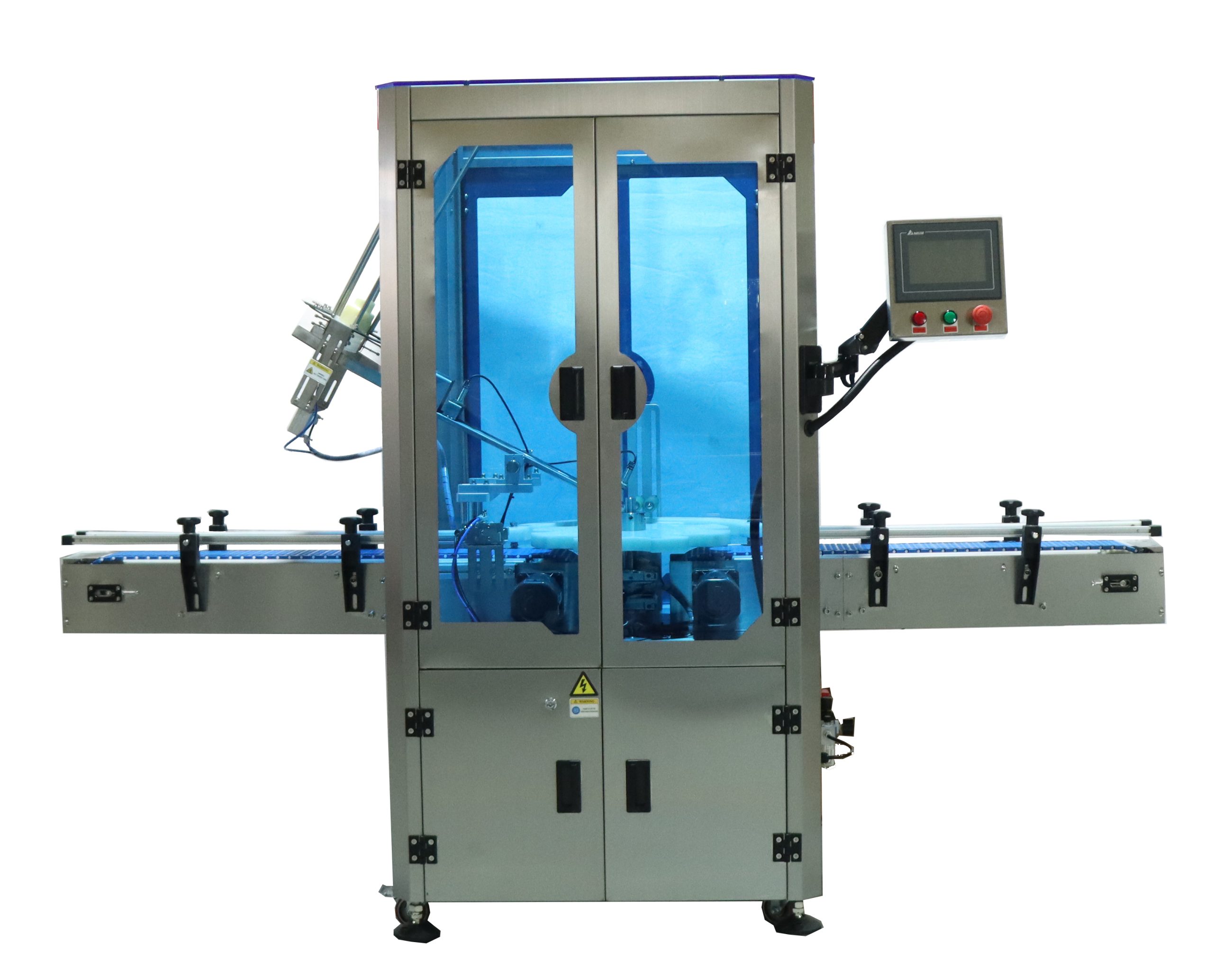

When it comes to packaging products in paper cans, ensuring that the contents remain fresh and uncontaminated is crucial. One way to achieve this is by using a dustproof cap capping machine. These machines are designed to securely seal paper cans with a dustproof cap, preventing any dust or contaminants from entering the container. However, with so many options available on the market, choosing the right dustproof cap capping machine for your specific needs can be a daunting task.

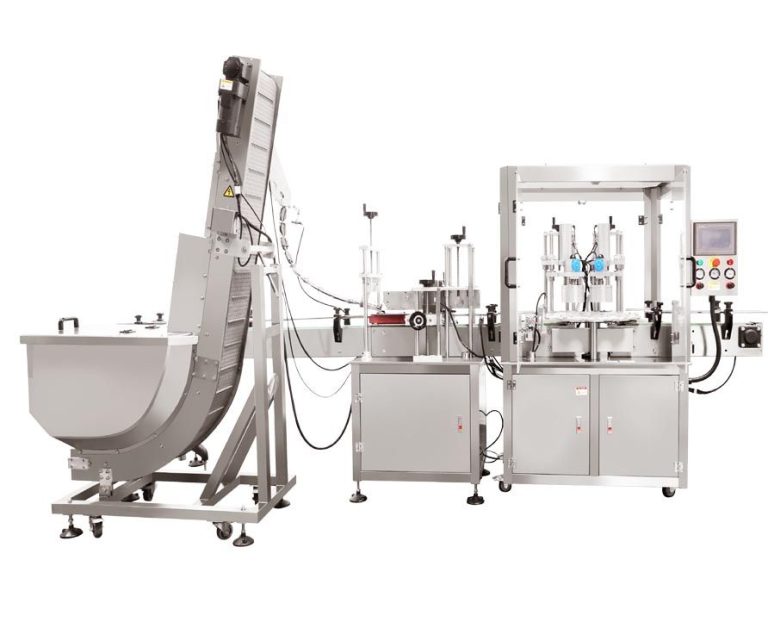

One of the first things to consider when selecting a dustproof cap capping machine is the size and shape of your paper cans. Different machines are designed to accommodate various sizes and shapes of containers, so it is important to choose a machine that is compatible with the dimensions of your paper cans. Additionally, consider the production capacity of the machine. If you have a high volume of paper cans to seal, you will need a machine that can keep up with your production demands.

Another important factor to consider is the type of dustproof cap that the machine is capable of applying. Some machines are designed to apply a specific type of cap, while others are more versatile and can accommodate a variety of cap styles. Consider the type of cap that will best suit your packaging needs, whether it be a screw-on cap, snap-on cap, or press-on cap.

In addition to the type of cap, consider the material of the cap as well. Dustproof caps come in a variety of materials, including plastic, aluminum, and composite materials. Each material has its own advantages and disadvantages, so it is important to choose a machine that is compatible with the type of cap material you plan to use.

When selecting a dustproof cap capping machine, it is also important to consider the level of automation that you require. Some machines are fully automated, while others require manual intervention at various stages of the capping process. Consider your production needs and budget when deciding on the level of automation that is right for your operation.

Furthermore, consider the ease of maintenance and cleaning of the machine. A dustproof cap capping machine that is easy to clean and maintain will help to ensure the longevity of the machine and prevent any contamination issues. Look for machines that are designed with easy access to critical components for maintenance and cleaning purposes.

Lastly, consider the reputation and reliability of the manufacturer when selecting a dustproof cap capping machine. Look for manufacturers with a proven track record of producing high-quality, reliable machines. Reading customer reviews and testimonials can also provide valuable insight into the performance and reliability of a particular machine.

In conclusion, choosing the right dustproof cap capping machine for your paper cans involves considering factors such as the size and shape of your containers, the type and material of the cap, production capacity, level of automation, ease of maintenance, and the reputation of the manufacturer. By carefully evaluating these factors and selecting a machine that meets your specific needs, you can ensure that your paper cans are securely sealed and protected from dust and contaminants.

-768x622.jpg)