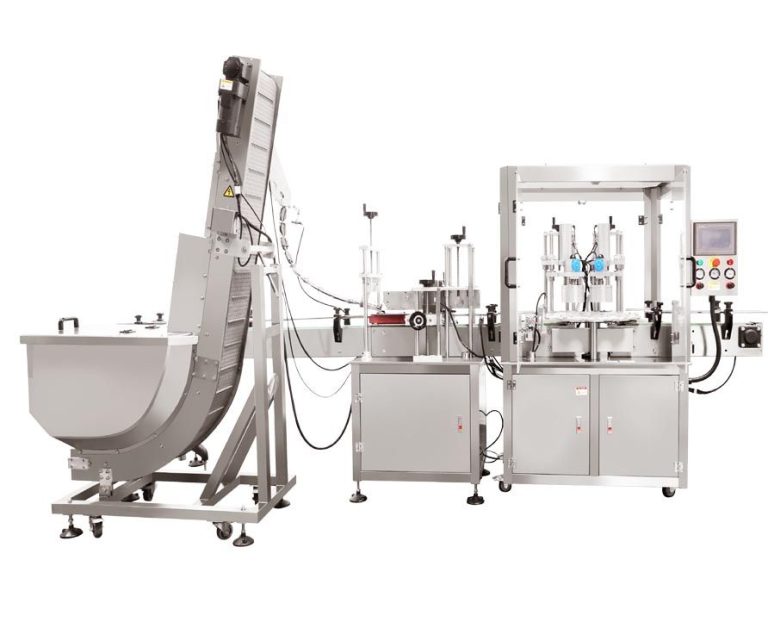

An automatic dual-head servo can seaming machine is a sophisticated piece of equipment designed for efficient and precise sealing of cans.

It works through a complex yet highly coordinated process. At its core, the machine has two seaming heads that operate simultaneously. The cans are placed in position, and a can body and a lid are brought together.

The servo system plays a crucial role in controlling the movement and pressure applied during the seaming process. It ensures precise alignment and consistent force to create a tight and secure seam.

The machine starts by gripping the can and lid firmly. Then, as the seaming heads rotate, they form the seam by folding and pressing the materials together. The servo technology allows for accurate adjustment of parameters such as speed, pressure, and timing to achieve the perfect seal.

Sensors and control systems monitor the entire process, making real-time adjustments to ensure each can is sealed with the same quality and integrity.

In summary, an automatic dual-head servo can seaming machine combines advanced technology and precise mechanics to provide a reliable and efficient method of sealing cans for various industries.