It seems we can’t find what you’re looking for. Perhaps searching can help.

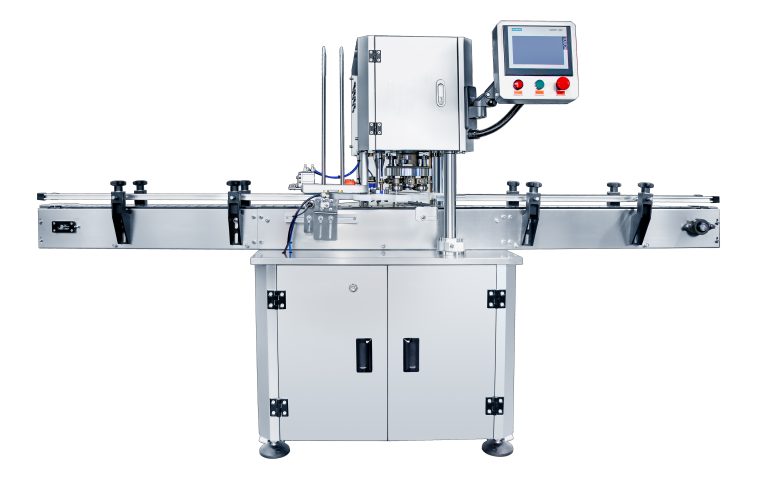

When purchasing a automatic vacuum can sealing machine several factors must be considered

Cost-effectiveness of Automatic Vacuum Can Sealing Machines When it comes to packaging food products, especially in cans, ensuring that the contents remain fresh and free from contaminants is crucial. This is where automatic vacuum can sealing machines come into play. These machines are designed to create a vacuum seal on…