Table of Contents

Proper Lubrication Techniques for Automatic Can Closing Machines

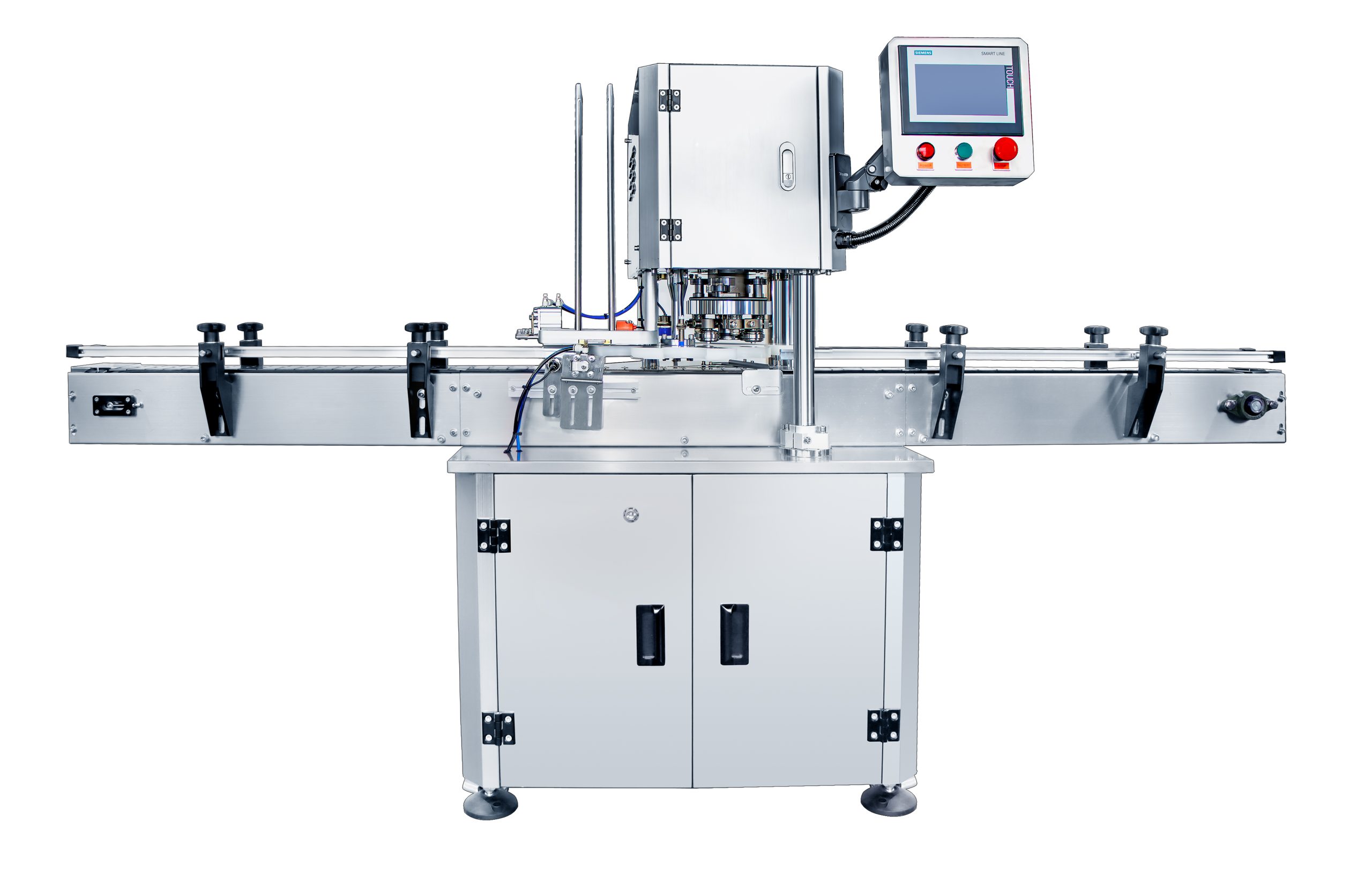

Automatic can closing machines are essential equipment in the food and beverage industry, as they help streamline the packaging process and ensure that cans are sealed properly. To keep these machines running smoothly and efficiently, proper maintenance is crucial. One key aspect of maintenance is ensuring that the machine is properly lubricated. In this article, we will discuss the importance of lubrication for automatic can closing machines and provide some tips on how to maintain them.

Lubrication plays a vital role in the operation of automatic can closing machines. It helps reduce friction between moving parts, which in turn reduces wear and tear on the machine. Proper lubrication also helps prevent overheating and ensures that the machine operates at optimal efficiency. Without adequate lubrication, the machine’s performance may suffer, leading to increased downtime and potential breakdowns.

When it comes to lubricating automatic can closing machines, there are a few key things to keep in mind. First and foremost, it is important to use the right type of lubricant. Different parts of the machine may require different types of lubricants, so it is essential to consult the manufacturer’s guidelines to determine the appropriate lubrication for each component. Using the wrong type of lubricant can cause damage to the machine and compromise its performance.

In addition to using the right type of lubricant, it is also important to apply the lubricant correctly. This means ensuring that the lubricant is applied in the right quantity and at the right intervals. Over-lubricating can lead to excess buildup, which can attract dirt and debris and cause the machine to malfunction. On the other hand, under-lubricating can result in increased friction and wear on the machine’s moving parts. It is important to follow the manufacturer’s recommendations for lubrication to ensure that the machine operates smoothly and efficiently.

Another important aspect of lubrication maintenance for automatic can closing machines is regular inspection. It is essential to regularly check the machine’s lubrication points to ensure that they are properly lubricated. This includes inspecting the oil levels, checking for any signs of wear or damage, and cleaning any excess lubricant buildup. Regular inspection can help identify any potential issues before they escalate into more significant problems, saving time and money on repairs.

In conclusion, proper lubrication is essential for maintaining automatic can closing machines. It helps reduce friction, prevent wear and tear, and ensure that the machine operates at optimal efficiency. By using the right type of lubricant, applying it correctly, and regularly inspecting the machine’s lubrication points, you can help prolong the life of your automatic can closing machine and keep it running smoothly for years to come. Remember to consult the manufacturer’s guidelines for specific lubrication recommendations and follow them diligently to ensure the best results.

Regular Inspection and Maintenance Schedule for Automatic Can Closing Machines

Automatic can closing machines are essential equipment in the food and beverage industry, ensuring that cans are securely sealed before they are distributed to consumers. To maintain the efficiency and longevity of these machines, it is crucial to implement a regular inspection and maintenance schedule. By following these guidelines, you can prevent breakdowns, reduce downtime, and ultimately save on costly repairs.

One of the first steps in maintaining an automatic can closing machine is to establish a routine inspection schedule. This should include daily, weekly, and monthly checks to identify any potential issues before they escalate. During daily inspections, operators should look for any signs of wear and tear on the machine components, such as belts, chains, and seals. Any loose or damaged parts should be replaced immediately to prevent further damage to the machine.

Weekly inspections should focus on more in-depth checks, such as lubricating moving parts and tightening any loose bolts or screws. It is also important to inspect the electrical components of the machine, ensuring that all connections are secure and free from corrosion. Any abnormalities should be addressed promptly to avoid electrical malfunctions that could lead to a breakdown.

Monthly inspections should involve a thorough cleaning of the machine, removing any debris or buildup that could affect its performance. This is also a good time to check the alignment of the machine components and make any necessary adjustments. Additionally, operators should inspect the safety features of the machine, such as emergency stop buttons and safety guards, to ensure they are functioning properly.

In addition to regular inspections, it is essential to follow a maintenance schedule to keep the automatic can closing machine in optimal condition. This should include tasks such as changing the oil in the machine’s gearbox, replacing worn-out parts, and calibrating the machine to ensure accurate sealing of cans. By following a maintenance schedule, you can extend the lifespan of the machine and prevent costly repairs down the line.

When performing maintenance on an automatic can closing machine, it is important to follow the manufacturer’s guidelines and recommendations. This may include using specific lubricants or tools, as well as following proper safety procedures to prevent accidents. If you are unsure about how to perform a particular maintenance task, it is best to consult the machine’s manual or contact the manufacturer for guidance.

In conclusion, maintaining an automatic can closing machine requires a combination of regular inspections and a structured maintenance schedule. By staying proactive and addressing any issues promptly, you can prevent breakdowns and ensure the machine operates efficiently. Remember to follow the manufacturer’s guidelines and recommendations when performing maintenance tasks, and always prioritize safety to protect both the machine and its operators. By investing time and effort into maintaining your automatic can closing machine, you can prolong its lifespan and maximize its performance.