The canned food industry has a long – standing history of providing convenient, shelf – stable food options to consumers around the world. Over the years, numerous advancements have been made to improve the quality, safety, and efficiency of the canning process. Among these innovations, the automatic negative pressure vacuum can seamer stands out as a true game – changer.

Table of Contents

A Breakthrough in Sealing Technology

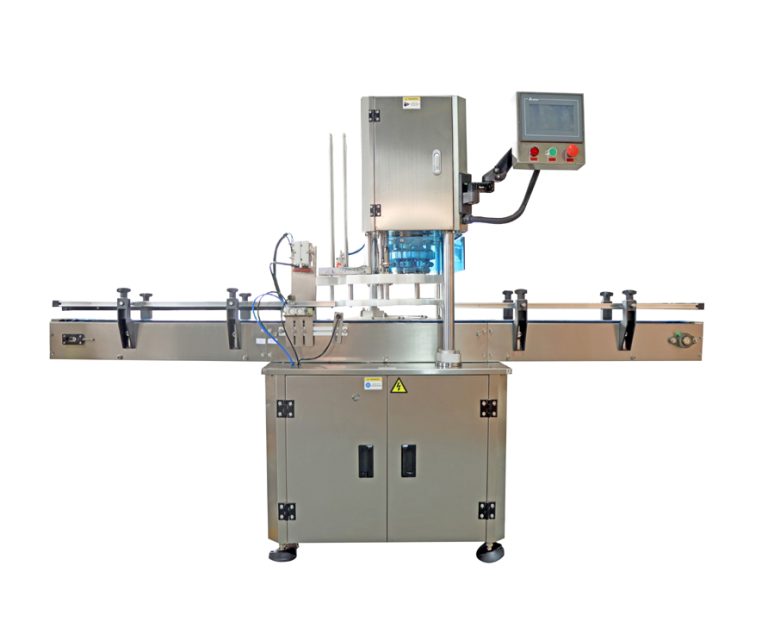

Traditional canning methods had their limitations. The presence of air inside the can could lead to oxidation, spoilage, and a shorter shelf – life. The automatic negative pressure vacuum can seamer addresses these issues head – on. This remarkable piece of equipment first creates a negative pressure environment within the can before sealing it.

The process begins when the can, filled with food, is placed in the seaming chamber. The machine then activates a vacuum system to remove the air from the can. As the air is sucked out, the pressure inside the can drops significantly. This negative pressure not only reduces the amount of oxygen present but also helps in achieving a more secure and airtight seal. Once the desired negative pressure is reached, the seaming mechanism precisely attaches the lid to the can body, creating a hermetic seal that keeps the food protected.

Preserving Food Quality

One of the most significant impacts of the automatic negative pressure vacuum can seamer is on the quality of canned food. By removing oxygen, it slows down the oxidation process. Oxidation can cause food to lose its color, flavor, and nutritional value. For instance, canned fruits may turn brown and lose their natural sweetness, and canned meats can develop a rancid taste.

With the negative pressure vacuum sealing, these problems are minimized. The food inside the can retains its original color, texture, and flavor for a much longer time. Consumers can enjoy canned products that taste almost as fresh as when they were first prepared. This has led to an increase in consumer satisfaction and a broader acceptance of canned food in the market.

Ensuring Food Safety

Food safety is a top concern in the canned food industry, and the automatic can seamer plays a crucial role in this area. The hermetic seal created by the machine acts as a barrier against external contaminants such as bacteria, mold, and dust. The negative pressure environment also inhibits the growth of aerobic microorganisms that require oxygen to survive.

This is especially important in preventing the growth of harmful bacteria like Clostridium botulinum, which can produce a deadly toxin in low – acid canned foods. By ensuring a high – quality seal and a low – oxygen environment, the automatic negative pressure vacuum can seamer significantly reduces the risk of foodborne illnesses, giving consumers peace of mind when purchasing canned products.

Improving Production Efficiency

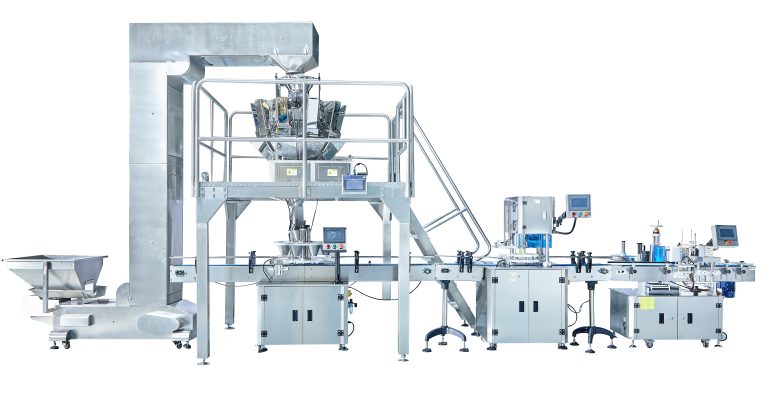

In addition to its benefits for food quality and safety, the automatic negative pressure vacuum can seamer has revolutionized the production process in the canned food industry. It is designed for high – speed operation, capable of sealing a large number of cans in a short period. This high throughput is essential for meeting the growing demand for canned food.

Moreover, the machine is highly automated, which reduces the need for manual labor. Workers can be assigned to other important tasks such as quality control and maintenance. The automation also ensures consistency in the sealing process, reducing the chances of human error. Each can is sealed to the same high standard, resulting in a more reliable and uniform product.

Shaping the Future of the Canned Food Industry

As the demand for convenient and high – quality food continues to rise, the automatic negative pressure vacuum can seamer will likely play an even more prominent role in the canned food industry. Manufacturers are constantly looking for ways to improve their products, and this technology provides a competitive edge.

Future developments may include further enhancements in speed, energy efficiency, and the ability to handle different types of cans and food products. The can seamer may also be integrated with other advanced technologies such as sensors and artificial intelligence for better quality control and process optimization.

In conclusion, the automatic negative pressure vacuum can seamer is a game – changer for the canned food industry. It has transformed the way canned food is produced, preserved, and consumed. By improving food quality, ensuring safety, and boosting production efficiency, it has set a new standard for the industry and will continue to shape its future.