Benefits of Implementing a Cashew Weighing Filling System

Cashew nuts are a popular snack enjoyed by people all over the world. With their rich, buttery flavor and crunchy texture, cashews are a versatile ingredient used in a variety of dishes, from salads to stir-fries to desserts. As the demand for cashews continues to grow, it is important for manufacturers to find efficient ways to package and distribute these delicious nuts. One solution that has been gaining popularity in recent years is the cashew weighing filling system.

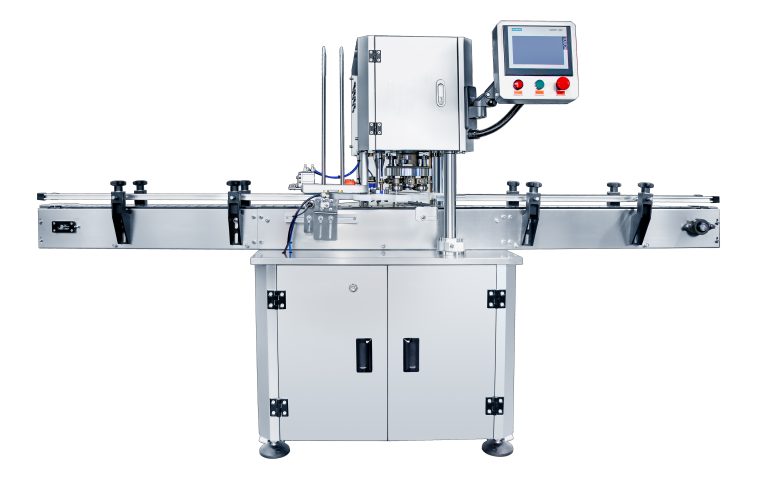

The cashew weighing filling system is a sophisticated piece of equipment that is designed to accurately weigh and fill containers with cashew nuts. This system is typically used in large-scale cashew processing facilities, where speed and precision are essential. By automating the weighing and filling process, manufacturers can increase their production efficiency and reduce the risk of human error.

One of the key benefits of implementing a cashew weighing filling system is the increased accuracy it provides. Manual weighing and filling processes are prone to errors, which can result in underfilled or overfilled containers. This not only leads to product waste but can also damage the reputation of the manufacturer. With a cashew weighing filling system, each container is filled with the exact amount of cashews, ensuring consistency and quality in every package.

In addition to accuracy, the cashew weighing filling system also offers increased speed and efficiency. Manual weighing and filling processes can be time-consuming and labor-intensive, requiring multiple workers to complete the task. With a cashew weighing filling system, the entire process is automated, allowing manufacturers to fill containers at a much faster rate. This not only increases production output but also reduces labor costs, making the system a cost-effective solution for cashew processing facilities.

Another benefit of the cashew weighing filling system is its versatility. This system can be easily adjusted to accommodate different container sizes and weights, making it suitable for a wide range of packaging needs. Whether manufacturers are filling small bags for retail sale or large containers for bulk distribution, the cashew weighing filling system can be customized to meet their specific requirements.

Furthermore, the cashew weighing filling system is also equipped with advanced technology that allows for real-time monitoring and data collection. Manufacturers can track the weight of each container as it is filled, ensuring that quality control standards are met. This data can also be used for inventory management and production planning, helping manufacturers optimize their operations and reduce waste.

Overall, the cashew weighing filling system offers a range of benefits for cashew processing facilities. From increased accuracy and efficiency to versatility and advanced technology, this system is a valuable investment for manufacturers looking to streamline their packaging processes. By implementing a cashew weighing filling system, manufacturers can ensure that their cashew nuts are packaged and distributed with precision and consistency, meeting the demands of consumers worldwide.