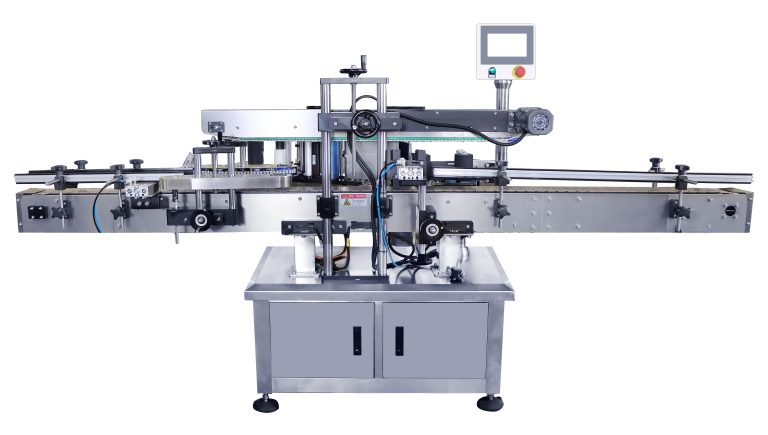

Benefits of Using an Automatic Bottle Labeling Machine with Adhesive Sticker Applicator An automatic bottle labeling machine with adhesive sticker applicator is a valuable tool for businesses looking to streamline their labeling process. This machine offers a range of benefits that can help improve efficiency, accuracy, and overall productivity. In…

Benefits of Using a Dustproof Cap Capping Machine for Paper Can In the manufacturing industry, efficiency and quality are key factors in ensuring the success of a business. One important aspect of production is the sealing of containers to protect the contents from external elements. When it comes to paper…

Benefits of Using a Canned Fruit Automatic Vacuum Capper Canned fruit is a popular choice for many consumers due to its convenience and long shelf life. However, ensuring that the canned fruit remains fresh and free from contamination is essential. This is where a canned fruit automatic vacuum capper comes…

Benefits of Using an Automatic Three Side Square Bottle Labeling Machine An automatic three side square bottle labeling machine is a valuable piece of equipment for businesses in various industries. This machine offers numerous benefits that can streamline the labeling process and improve efficiency. In this article, we will explore…

The Automatic Ketchup Negative Pressure Vacuum Sealing Machine is a specialized tool that has transformed the packaging of ketchup. Let’s delve into its distinctive features and how it ensures the excellence of ketchup packaging. This machine is meticulously engineered to provide a precise negative pressure vacuum sealing for ketchup containers….

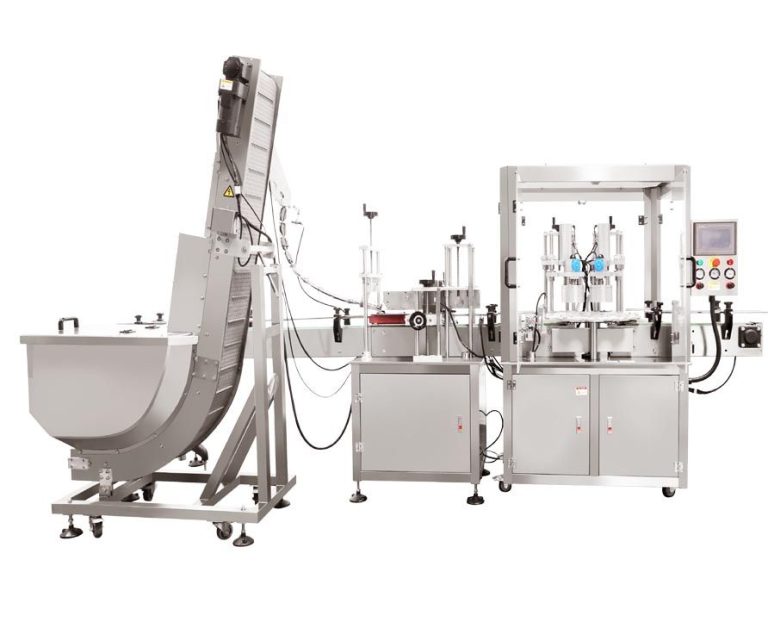

The Automatic Powder Bottle Mixing Filling Capping Labeling Line is a revolutionary solution that brings efficiency and precision to the powder packaging process. This integrated line seamlessly combines multiple essential steps, starting from the mixing of the powder to the final labeling of the bottles. The automatic mixing ensures that…