It seems we can’t find what you’re looking for. Perhaps searching can help.

“Why Auger Filling Technology is Perfect for Fine Powders (Pharma, Food, Chemicals)”

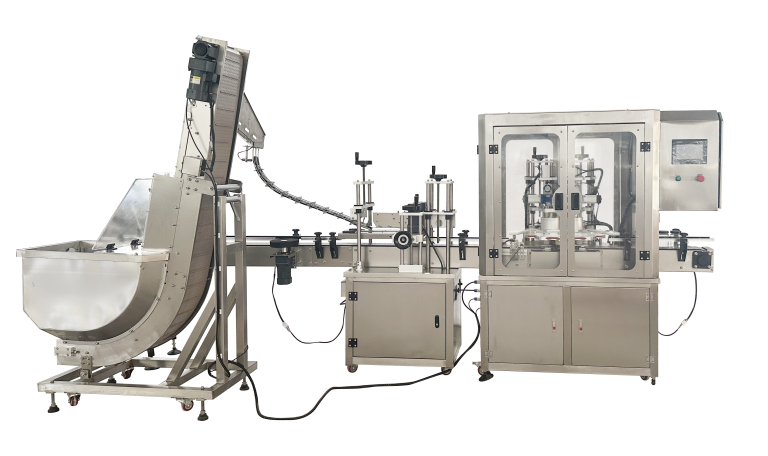

In the fields of pharma, food, and chemicals, the handling and packaging of fine powders require precise and reliable methods. Auger filling technology emerges as the ideal choice for several compelling reasons. Firstly, auger fillers offer exceptional accuracy when dealing with fine powders. The controlled rotation of the auger screw…