Table of Contents

Benefits of Using Fully Automatic Milk Powder Vacuum Filling Nitrogen Sealing Machine

In the food industry, packaging plays a crucial role in maintaining the quality and freshness of products. When it comes to milk powder, proper packaging is essential to prevent spoilage and ensure a longer shelf life. One of the most effective ways to package milk powder is by using a fully automatic milk powder vacuum filling nitrogen sealing machine.

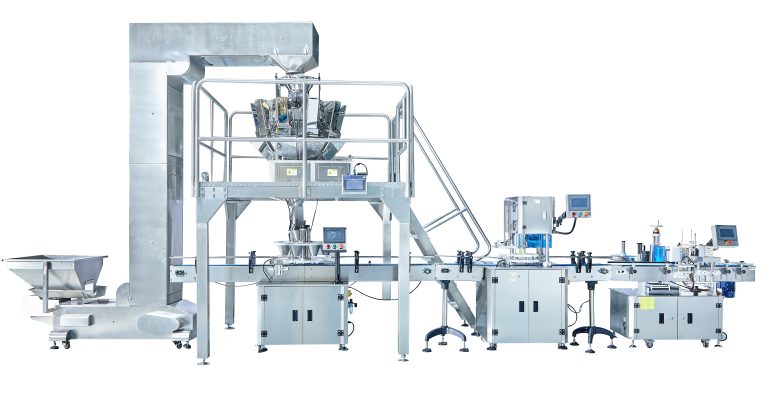

This advanced machine is designed to streamline the packaging process and ensure that the milk powder is sealed in airtight containers to prevent moisture and oxygen from affecting its quality. By using nitrogen gas to create a protective barrier inside the packaging, the machine helps to extend the shelf life of the milk powder and preserve its flavor and nutritional value.

One of the key benefits of using a fully automatic milk powder vacuum filling nitrogen sealing machine is its efficiency. This machine is capable of filling and sealing a large number of containers in a short amount of time, making it ideal for high-volume production. By automating the packaging process, companies can increase their productivity and reduce labor costs.

In addition to its efficiency, the fully automatic milk powder vacuum filling nitrogen sealing machine also offers a high level of precision. The machine is equipped with sensors and controls that ensure accurate filling and sealing of the containers, eliminating the risk of human error. This precision helps to maintain the quality and consistency of the milk powder packaging, which is essential for building consumer trust and loyalty.

Another benefit of using this machine is its versatility. The fully automatic milk powder vacuum filling nitrogen sealing machine can be customized to accommodate different container sizes and shapes, allowing companies to package their milk powder in a variety of formats. This flexibility is especially useful for companies that produce a range of milk powder products and need a packaging solution that can adapt to their changing needs.

Furthermore, the fully automatic milk powder vacuum filling nitrogen sealing machine is designed to meet the highest standards of hygiene and safety. The machine is made of food-grade materials that are easy to clean and sanitize, ensuring that the milk powder is packaged in a clean and sanitary environment. This is essential for preventing contamination and ensuring the safety of the product for consumers.

Overall, the benefits of using a fully automatic milk powder vacuum filling nitrogen sealing machine are clear. From its efficiency and precision to its versatility and hygiene, this machine offers a comprehensive packaging solution for companies in the food industry. By investing in this advanced technology, companies can improve their production processes, enhance the quality of their products, and ultimately, increase their competitiveness in the market.

How to Choose the Right Fully Automatic Milk Powder Vacuum Filling Nitrogen Sealing Machine for Your Business

In the food industry, packaging plays a crucial role in maintaining the quality and freshness of products. When it comes to milk powder, ensuring that it is properly sealed and protected from external factors is essential to prevent spoilage and maintain its shelf life. This is where a fully automatic milk powder vacuum filling nitrogen sealing machine comes into play.

These machines are designed to efficiently fill containers with milk powder, remove any excess air through vacuum sealing, and then seal the containers with nitrogen to prevent oxidation and maintain the product’s quality. Choosing the right fully automatic milk powder vacuum filling nitrogen sealing machine for your business is crucial to ensure smooth operations and high-quality packaging.

When looking for a fully automatic milk powder vacuum filling nitrogen sealing machine, there are several factors to consider. Firstly, you need to assess the production capacity of the machine. Depending on the size of your business and the demand for milk powder products, you will need to choose a machine that can meet your production requirements. Look for machines that offer a high filling speed and can handle a large volume of containers per hour.

Another important factor to consider is the level of automation of the machine. Fully automatic machines are equipped with advanced technology that allows them to operate with minimal human intervention. This not only increases efficiency but also reduces the risk of errors in the packaging process. Look for machines that offer features such as automatic container feeding, filling, sealing, and nitrogen flushing to streamline your production process.

In addition to automation, it is important to consider the versatility of the machine. Look for machines that can handle a variety of container sizes and shapes to accommodate different packaging requirements. This will allow you to package milk powder in different types of containers, catering to the diverse needs of your customers.

Furthermore, consider the ease of maintenance and cleaning of the machine. Regular maintenance is essential to ensure the smooth operation of the machine and prevent breakdowns. Look for machines that are easy to clean and maintain, with accessible parts that can be easily replaced or repaired when needed.

When choosing a fully automatic milk powder vacuum filling nitrogen sealing machine, it is also important to consider the level of customization and flexibility it offers. Look for machines that can be easily adjusted to accommodate different packaging requirements, such as varying fill levels or sealing parameters. This will allow you to adapt to changing market demands and offer a wider range of packaging options to your customers.

In conclusion, choosing the right fully automatic milk powder vacuum filling nitrogen sealing machine for your business is essential to ensure efficient packaging operations and high-quality products. Consider factors such as production capacity, level of automation, versatility, ease of maintenance, and customization when selecting a machine that meets your business needs. By investing in a high-quality machine, you can streamline your packaging process, improve product quality, and ultimately enhance customer satisfaction.

Maintenance Tips for Fully Automatic Milk Powder Vacuum Filling Nitrogen Sealing Machine

Maintaining a fully automatic milk powder vacuum filling nitrogen sealing machine is crucial to ensure its optimal performance and longevity. Regular maintenance not only helps prevent breakdowns and costly repairs but also ensures that the machine operates efficiently, producing high-quality milk powder products. In this article, we will discuss some essential maintenance tips for a fully automatic milk powder vacuum filling nitrogen sealing machine.

First and foremost, it is important to regularly clean the machine to prevent the buildup of milk powder residue and other contaminants. This can be done by wiping down the exterior of the machine with a damp cloth and using a brush to remove any debris from the nozzles, valves, and other components. Additionally, it is recommended to use a mild detergent or cleaning solution to thoroughly clean the machine’s interior parts, such as the vacuum chamber and sealing mechanism.

In addition to cleaning, it is important to regularly inspect the machine for any signs of wear and tear. This includes checking for loose or damaged parts, leaks, and unusual noises during operation. If any issues are detected, they should be addressed promptly to prevent further damage to the machine.

Another important maintenance tip is to regularly lubricate the moving parts of the machine to ensure smooth operation. This includes lubricating the conveyor belts, gears, and other components that require lubrication. It is important to use the appropriate type of lubricant recommended by the manufacturer to prevent damage to the machine.

Furthermore, it is important to regularly calibrate the machine to ensure accurate filling and sealing of milk powder products. This can be done by following the manufacturer’s instructions for calibration and making any necessary adjustments to the machine’s settings. Regular calibration helps maintain the machine’s accuracy and consistency in filling and sealing milk powder products.

It is also important to regularly check and replace any worn or damaged parts of the machine. This includes replacing worn seals, gaskets, and other components that may affect the machine’s performance. It is important to use genuine replacement parts recommended by the manufacturer to ensure compatibility and optimal performance.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the fully automatic milk powder vacuum filling nitrogen sealing machine. This includes performing routine maintenance tasks such as cleaning, lubricating, inspecting, and calibrating the machine at regular intervals. Following the manufacturer’s maintenance schedule helps ensure that the machine operates efficiently and produces high-quality milk powder products.

In conclusion, maintaining a fully automatic milk powder vacuum filling nitrogen sealing machine is essential to ensure its optimal performance and longevity. By following these maintenance tips, you can prevent breakdowns, costly repairs, and ensure that the machine operates efficiently, producing high-quality milk powder products. Regular cleaning, inspection, lubrication, calibration, and replacement of worn parts are key to maintaining the machine in top condition. By following the manufacturer’s recommended maintenance schedule, you can prolong the life of your fully automatic milk powder vacuum filling nitrogen sealing machine and maximize its productivity.