Table of Contents

Benefits of Using Fully Automatic Albumen Powder Filling Machine

Albumen powder, also known as egg white powder, is a versatile ingredient used in a variety of food products, including baked goods, confectionery, and protein supplements. To meet the growing demand for albumen powder, manufacturers are turning to fully automatic albumen powder filling machines. These machines offer numerous benefits that can improve efficiency, accuracy, and overall product quality.

One of the key benefits of using a fully automatic albumen powder filling machine is increased production speed. These machines are designed to fill containers with albumen powder quickly and efficiently, allowing manufacturers to meet high production demands without sacrificing quality. By automating the filling process, manufacturers can significantly increase their output and reduce production time, ultimately improving their bottom line.

In addition to increased production speed, fully automatic albumen powder filling machines also offer improved accuracy. These machines are equipped with advanced technology that ensures precise filling of containers, reducing the risk of overfilling or underfilling. This level of accuracy is crucial in ensuring consistent product quality and reducing waste. By using a fully automatic filling machine, manufacturers can minimize product loss and ensure that every container is filled to the exact specifications.

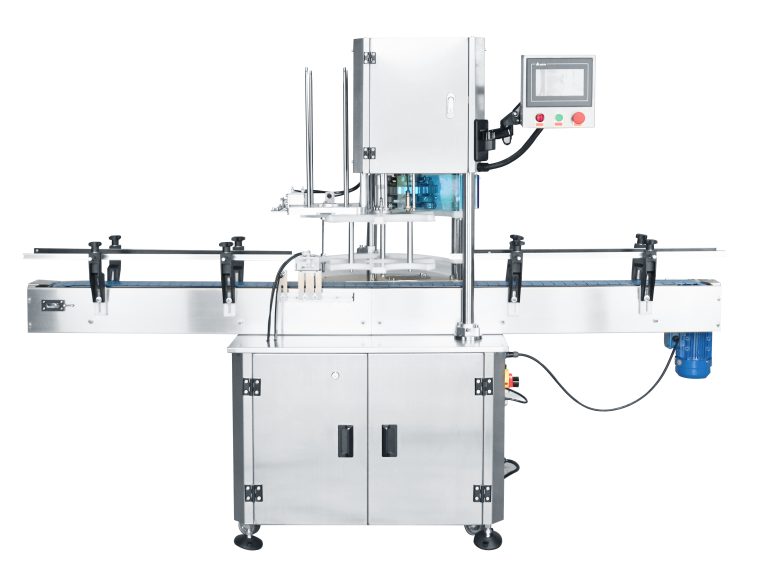

Another benefit of using a fully automatic albumen powder filling machine is improved hygiene and cleanliness. These machines are designed to meet strict hygiene standards, with features such as stainless steel construction and easy-to-clean surfaces. By automating the filling process, manufacturers can reduce the risk of contamination and ensure that their products meet the highest safety standards. This is particularly important in the food industry, where cleanliness and hygiene are paramount.

Fully automatic albumen powder filling machines also offer greater flexibility and versatility. These machines can be easily adjusted to accommodate different container sizes and filling volumes, allowing manufacturers to produce a wide range of products with ease. This flexibility is essential for meeting the diverse needs of customers and adapting to changing market demands. By investing in a fully automatic filling machine, manufacturers can streamline their production process and increase their product offerings.

Furthermore, fully automatic albumen powder filling machines are easy to operate and require minimal training. These machines are equipped with user-friendly interfaces and intuitive controls, making them accessible to operators of all skill levels. By simplifying the filling process, manufacturers can reduce the risk of human error and ensure consistent product quality. This ease of operation also allows manufacturers to quickly switch between different products and production runs, maximizing efficiency and productivity.

In conclusion, fully automatic albumen powder filling machines offer numerous benefits that can help manufacturers improve their production process and product quality. From increased production speed and accuracy to improved hygiene and flexibility, these machines are a valuable investment for any manufacturer looking to streamline their operations. By investing in a fully automatic filling machine, manufacturers can enhance their efficiency, reduce waste, and ultimately increase their competitiveness in the market.

How to Choose the Right Fully Automatic Albumen Powder Filling Machine for Your Business

In the world of manufacturing and packaging, efficiency is key. When it comes to filling albumen powder into containers, having the right equipment can make all the difference. Fully automatic albumen powder filling machines are designed to streamline the filling process, increasing productivity and reducing the risk of errors. However, with so many options available on the market, choosing the right machine for your business can be a daunting task.

One of the first things to consider when selecting a fully automatic albumen powder filling machine is the production capacity of your business. Different machines are designed to handle different volumes of powder, so it’s important to choose a machine that can keep up with your production needs. If your business is small or just starting out, a machine with a lower production capacity may be sufficient. However, if you have a high-volume operation, you’ll want to invest in a machine that can handle larger quantities of powder.

Another important factor to consider is the type of containers you will be filling with albumen powder. Fully automatic albumen powder filling machines come in a variety of configurations to accommodate different container sizes and shapes. Some machines are designed to fill bottles, while others are better suited for filling bags or pouches. It’s important to choose a machine that is compatible with the containers you will be using to ensure a smooth and efficient filling process.

In addition to production capacity and container compatibility, it’s also important to consider the level of automation you require. Fully automatic albumen powder filling machines come in a range of automation levels, from basic machines that require manual intervention to fully automated machines that can operate without any human assistance. The level of automation you choose will depend on your production needs and budget. While fully automated machines offer the highest level of efficiency, they also tend to be more expensive than semi-automatic or manual machines.

When selecting a fully automatic albumen powder filling machine, it’s also important to consider the overall build quality and reliability of the machine. Look for machines that are made from high-quality materials and are built to last. A reliable machine will help minimize downtime and maintenance costs, ensuring that your production line runs smoothly and efficiently.

Finally, don’t forget to consider the after-sales support and service offered by the manufacturer. A fully automatic albumen powder filling machine is a significant investment, so it’s important to choose a manufacturer that offers excellent customer support and service. Look for manufacturers that provide training, maintenance, and technical support to help you get the most out of your machine.

In conclusion, choosing the right fully automatic albumen powder filling machine for your business is a crucial decision that can have a significant impact on your production efficiency and overall success. By considering factors such as production capacity, container compatibility, automation level, build quality, and after-sales support, you can select a machine that meets your specific needs and helps your business thrive. With the right machine in place, you can streamline your filling process, increase productivity, and achieve your business goals.

Maintenance Tips for Fully Automatic Albumen Powder Filling Machine

Maintaining a fully automatic albumen powder filling machine is crucial to ensure its optimal performance and longevity. Regular maintenance not only prevents breakdowns and costly repairs but also ensures that the machine operates efficiently, producing high-quality filled products consistently. In this article, we will discuss some essential maintenance tips for a fully automatic albumen powder filling machine.

First and foremost, it is important to follow the manufacturer’s guidelines for maintenance and servicing. These guidelines typically include recommended maintenance schedules, lubrication requirements, and troubleshooting tips. By adhering to these guidelines, you can prevent unnecessary wear and tear on the machine and avoid potential issues that may arise from improper maintenance practices.

One of the most important maintenance tasks for a fully automatic albumen powder filling machine is cleaning. Regular cleaning of the machine’s components, such as the hopper, filling nozzles, and conveyor belts, helps prevent the buildup of powder residue and ensures that the machine operates smoothly. It is recommended to clean the machine after each use to prevent contamination and maintain hygiene standards.

In addition to regular cleaning, it is essential to inspect the machine for any signs of wear or damage. Check for loose or damaged parts, worn-out seals, and any other issues that may affect the machine’s performance. Addressing these issues promptly can prevent further damage and ensure that the machine continues to operate efficiently.

Another important maintenance task is lubrication. Proper lubrication of the machine’s moving parts, such as gears, bearings, and conveyor belts, helps reduce friction and wear, prolonging the machine’s lifespan. It is important to use the correct type of lubricant recommended by the manufacturer and to follow the lubrication schedule to ensure optimal performance.

Regular calibration of the machine is also crucial for maintaining accuracy in filling volume and weight. Over time, the machine’s settings may drift, leading to inaccuracies in filling. By calibrating the machine regularly, you can ensure that it delivers precise and consistent filling results, meeting quality standards and customer expectations.

In addition to these maintenance tasks, it is important to train operators on proper machine operation and maintenance procedures. Operators should be familiar with the machine’s functions, safety protocols, and troubleshooting techniques to prevent accidents and minimize downtime. Regular training sessions can help operators stay informed about best practices and ensure that the machine is operated correctly.

Overall, proper maintenance of a fully automatic albumen powder filling machine is essential for its efficient operation and longevity. By following the manufacturer’s guidelines, cleaning the machine regularly, inspecting for wear and damage, lubricating moving parts, calibrating the machine, and training operators, you can ensure that the machine performs at its best and delivers high-quality filled products consistently. Investing time and effort in maintenance now can save you time and money in the long run by preventing breakdowns and ensuring smooth operation.