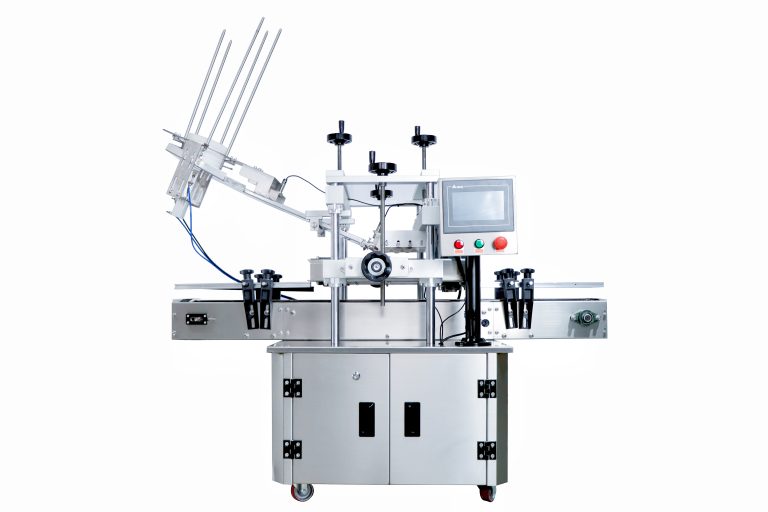

In the highly regulated world of pharmaceutical packaging, achieving perfection is not just a goal but a necessity. The 4-wheel cappers have emerged as a game-changer when it comes to sealing sterile vials.

The 4-wheel design provides a balanced and uniform application of force, crucial for ensuring a tight and leak-proof seal on the delicate sterile vials. This precise distribution of pressure helps maintain the integrity of the vials and the sterility of the contents within.

These cappers are engineered with meticulous attention to detail. They are made from materials that meet the strictest standards of cleanliness and hygiene, preventing any contamination during the sealing process.

The speed and efficiency of 4-wheel cappers are also remarkable. They can handle a large volume of vials in a short period, without compromising on the quality of the seal. This is essential in meeting the demanding production schedules of the pharmaceutical industry.

The advanced control systems of these machines allow for precise adjustments based on the specific requirements of different vial sizes and cap types. This flexibility ensures that each vial is sealed perfectly, regardless of variations.

Moreover, 4-wheel cappers are often equipped with monitoring and validation features to provide documentation and proof of the sealing process’s integrity. This is vital for compliance with regulatory requirements and quality control.

In conclusion, the 4-wheel cappers have perfected pharmaceutical packaging for sterile vial sealing, combining precision, speed, hygiene, and compliance to meet the rigorous demands of the industry and safeguard the quality and safety of pharmaceutical products.